- Machine-tools

- Machine Tool Accessory

- Power chuck

- Applied Robotics

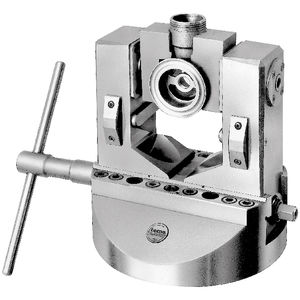

Power chuck MDE series steelprecisionself-centering

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Other characteristics

- steel, precision, self-centering, hydraulic, indexing, automatic clamping

- Outer diameter

Min.: 160 mm

(6 in)Max.: 300 mm

(12 in)

Description

INDEXING CHUCK WITH AUTOMATIC CLAMPING AND INDEXING – (8×45°)

MDE is an automatic indexing chuck with hydraulic clamping and indexing.

It is not self-centering.

ADVANTAGES

• made in special high resistance hardened and cementing 60HRC steel UNI18NiCrMo5, to maintain a high degree of precision, reliability and quality

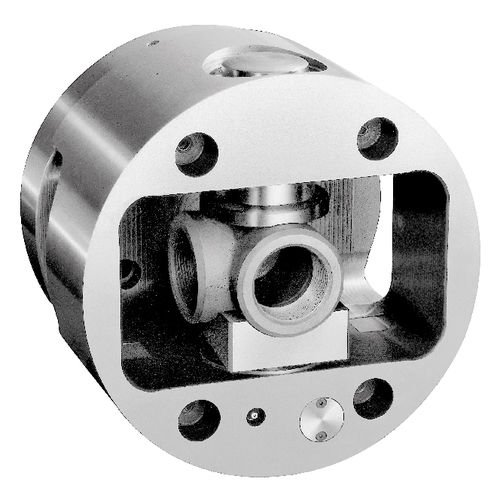

• indexing movement (tecnomors patent) simple reliable with only a piston that works in rotation and in clamping position. Indexing precision ± 1’

• guiding system of clamping and of the indexing mechanism.

This system uses 2 pre-loaded solid straight roller radially and 1 axial bearing

• seals against contamination by coolant, chips or dust

• constant and long lasting precision

• easy installation to the machine

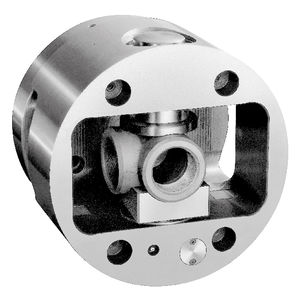

• the chuck is connected to the rear rotating oil manifold thanks to the nest tube.

This tube system is supplied with grinding hardened steel clutchs

• centrifugal force compensation system for parts susceptible to deformations to obtain an higher productivity performance

• indexing control device

• a good automation system level grows using robot to load and to unload workpieces

• indexing process is possible also in rotation position to allow a fast indexing position passage. The rotation speed has to be not at the maximum power

• indexing takes, with position control, approx. 2-4 seconds per 90°, depending on the size of the chuck

• very simple hydraulic system based on 2 indexing mechanism ports, 2 clamping pistons ports and 1 manifold drain

• the chucking piston is connected to a safety device and keeps the working securely gripped in the jaws even in the event of a complete pressure loss

Catalogs

No catalogs are available for this product.

See all of Applied Robotics‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.