- Industrial machines and equipment

- Surface Treatment

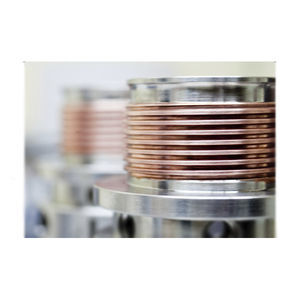

- Stainless steel passivation

- Applied Total Control Treatment Pte Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Stainless steel passivation for aeronauticsISO 9001

Add to favorites

Compare this product

Characteristics

- Type of substrate

- stainless steel

- Applications

- for aeronautics

- Certifications

- ISO 9001

Description

Our plating house offers the Passivation process for customers that wish to further increase the corrosion resistance of stainless-steel components.

The added benefit of performing Passivation stems from the fact it has a secondary function of removing exogenous iron from the surface of the substrate, making it easy to obtain a clean finish.

Passivation is a chemical dissolution process to remove exogenous iron or iron compounds from the surface of a stainless-steel substrate, usually by a treatment using an acid solution that will remove the surface contamination but will not significantly affect the stainless steel itself. Also, passivation is the chemical treatment of stainless steel with a mild oxidant, using a nitric acid solution, to enhance the spontaneous formation of the protective passive film.

Other Applied Total Control Treatment Pte Ltd products

Electroplating

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Anodic oxidation with coloring

- Painting

- ISO 9001 anodic oxidation

- Passivation

- Powder coating

- Polishing

- Zinc-plating

- Automotive anodic oxidation

- ISO 9001 passivation

- Steel passivation

- Medical anodizing

- Chrome plating

- Phosphating

- ISO 9001 phosphating

- ISO 9001 polishing

- Individual anodizing

- ISO 9001 powder coating

- ISO 9001 zinc-plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.