- Industrial machines and equipment

- Surface Treatment

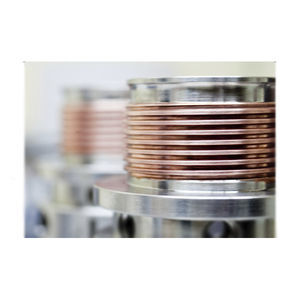

- Electrolytic tinning

- Applied Total Control Treatment Pte Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Electrolytic tinning coppernickelautomotive

Add to favorites

Compare this product

Characteristics

- Type

- electrolytic

- Substrate

- copper, nickel

- Applications

- automotive

- Certifications

- ISO 9001

Description

Equipped with years of experience in Tin plating, this is a well-established process that is applied extensively for ferrous and non-ferrous materials. For years, our numerous customers from the Food & Beverage industries have been the beneficiaries of the quality tin-plated goods we produce.

Tin is a silver-colored, ductile metal whose major purpose is to promote solderability to otherwise unsolderable base metals. Tin has generally good depositing characteristics over a wide range of part geometry.

Main Application / Advantages

The tin-plating process is applied extensively to protect both ferrous and non-ferrous substrates. Tin being non-toxic, ductile and corrosion resistant is frequently used for the food processing industry. The excellent ductility of tin allows a tin-coated base metal sheet to be formed into a variety of shapes without damage to the surface tin layer. It provides sacrificial protection for copper, nickel and other non-ferrous metals, but not for steel.

Tin protects the base metal from oxidation and preserves its solderability, properties ideal for the electronics industry.

Other Applied Total Control Treatment Pte Ltd products

Electroplating

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Anodic oxidation with coloring

- Painting

- ISO 9001 anodic oxidation

- Passivation

- Powder coating

- Polishing

- Zinc-plating

- Automotive anodic oxidation

- ISO 9001 passivation

- Steel passivation

- Medical anodizing

- Chrome plating

- Phosphating

- ISO 9001 phosphating

- ISO 9001 polishing

- Individual anodizing

- ISO 9001 powder coating

- ISO 9001 zinc-plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.