- Industrial machines and equipment

- Surface Treatment

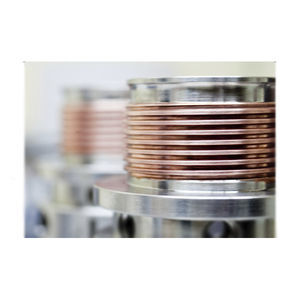

- Electronic polishing

- Applied Total Control Treatment Pte Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Electronic polishing individual

Add to favorites

Compare this product

Characteristics

- Applications

- for electronics

- Production method

- individual

Description

Chemical polishing is performed current less, meaning no extra time and effort is needed for electric contacting and installation of cathodes. The part is deburred and abraded through chemical removal all over the part’s surface.

The components are mounted on racks individually or loosely collected in baskets and drums and then immersed into the polishing bath.

This process requires control of time and bath temperature to assure the accuracy of removal on edges and surfaces within very narrow tolerances.

Other Applied Total Control Treatment Pte Ltd products

Electroplating

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Anodic oxidation with coloring

- Painting

- ISO 9001 anodic oxidation

- Passivation

- Powder coating

- Polishing

- Zinc-plating

- Automotive anodic oxidation

- ISO 9001 passivation

- Steel passivation

- Medical anodizing

- Chrome plating

- Phosphating

- ISO 9001 phosphating

- ISO 9001 polishing

- Individual anodizing

- ISO 9001 powder coating

- ISO 9001 zinc-plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.