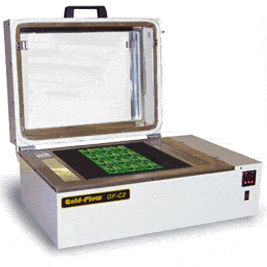

Reflow soldering machine ERO-500for printed circuits

Add to favorites

Compare this product

Characteristics

- Technique

- reflow

- Applications

- for printed circuits

Description

Reflow oven with five (5) top and five (5) bottom vertical heating zones, the ERO-500 is an economic solution for low to medium volume production runs. Utilizing plenum convection heating technology, the ERO-500 provides uniform temperature profiling across the entire PCB board for enhanced SMT process control. With a maximum high soldering temperature of 320°C, the ERO-500 is compatible with most lead and lead-free solder paste profiles.

5 vertical heating zones plus 1 cooling zone

Production status light tower included

Clamshell hood design with mechanical struts

Mesh belt or Edge rail conveyor units available

Real time graphic temperature profiler to assist in profiling of board

On-board LCD controller for easy and flexible programming control of reflow profile parameters

The easy to program on-board LCD with graphic user interface enables independent zone programming and maximum flexibility in profile parameter control.

Each heating zone is independently programmable and easily controlled through the on-board LCD controller

Reflow profiling capability with on-board programming and ability to add

three thermocouples for specific board locations.

Reflow oven is Lead and Lead-free compatible

PLUS, DDM is a true reflow oven manufacturer: designing, building, and customizing systems AND still selling parts for 30-year-old units - not a reseller

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.