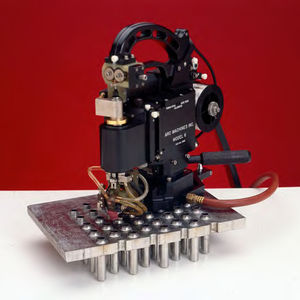

Arc welding head 96tube-to-tubesheetautomaticclosed

Add to favorites

Compare this product

Characteristics

- Technique

- arc, tube-to-tubesheet

- Other characteristics

- automatic, closed, for tubes

Description

The Model 96 is an automated weld head designed for high-speed, high-production autogenous welding of tubes to tubesheet. Welds made with this head, utilizing the GTAW (TIG) welding process, can pass the most rigid specifications.

The weld head is held in place on the tube to be welded by an expanding mandrel. This mandrel is actuated by a single button, conveniently located in the handle. Actuation of the mandrel holds the weld head firmly to the tubesheet and positions the torch concentric to the tube to be welded. The Model 96 features a completely enclosed purge chamber. The gas chamber eliminates the use of gas cups and provides superior shielding for materials which oxidize easily, such as titanium.

Rugged, reliable tube-to-tubesheet weld head suited for high-production applications

Makes autogenous GTAW (TIG) welds on flush or slightly projected tubes.

Single or multi-pass welds

Self-supporting on tubesheet, pneumatically operated

One-button operation, quick mount and dismount

Welds in any position, including overhead

VIDEO

Catalogs

Related Searches

- Welding generator

- Arc welding generator

- Automatic welding head

- Mobile welding generator

- Orbital welding head

- Arc welding head

- TIG welding generator

- Orbital welding machine

- Closed welding head

- Tube welding head

- GTAW welding head

- Open welding head

- Pipe orbital welding machine

- Arc orbital welding machine

- Automatic orbital welding machine

- Semi-automatic orbital welding machine

- Precision orbital welding machine

- Precision metal joining welding head

- Manual orbital welding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.