Articulated robot for welding

Add to favorites

Compare this product

Characteristics

- Type

- articulated

- Function

- for welding

Description

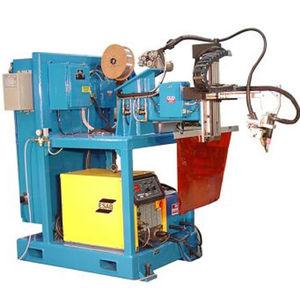

ROBOTIC FLUX CORE WELDING OF PIPE COUPLINGS

As it indexes the turntable, the robot cuts the wire in preparation for touch sensing

Uses touch sense to find the location of the weld on the part

The operator can safely load and unload parts while the robot welds

After a certain amount of welds, the torch cleaning station automatically cleans the torch

The three-step torch cleaning station reams weld spatter of the nozzle, cuts the wire to length, and applies anti-spatter inside the nozzle

The robot can be brought down to a comfortable working height at the touch of a button to change wire or tools

Because of the skid-mounted design, the machine can be quickly and easily installed, and moved around any space as necessary

The E-stop safety design is built in, as well as a laser detection system that protects the operator

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogsRelated Searches

- Welding system

- Industrial robot

- Automatic welding system

- Articulated robot

- 6-axis robot

- Metal welding system

- Arc welding system

- Precision welding system

- Manual welding system

- Welding robot

- Steel welding system

- CNC welding system

- Cobot

- Pipe welding system

- Robotic welding system

- Vertical welding system

- Horizontal welding system

- 3-axis welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.