- Products

- Automatic cladding machine

- Arc Specialties

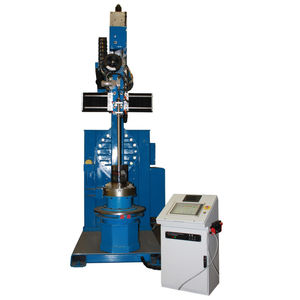

Automatic cladding machine ARC-05HVTE

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

HORIZONTAL, VERTICAL AND TILT CLADDING SYSTEM

Available in 2500lb or 6500lb capacity.

The ARC-05HVTe is an automated system that has the capability to weld in the horizontal and vertical position, or and any angle between the 0 and 90 degree positions on the ID and OD of cylindrical parts.

The ability to position part improves bead shape, weld chemistry and improves overall ease of operation and usability of welding process at high deposition rates.

ARC Specialties’ elbow cladding technology performs on-the-fly adjustments of the weld parameters, torch position and torch oscillation as the cross-sectional geometry of the elbow changes throughout the course of the welding process. The system’s software enables operators to simply touch off on two points of the elbow’s ID to generate an automated weld path.

The PLC control system has parameter feedback and overrides for automatic welding. The operator pendant is a touch screen with graphical user interface for ease of operation. The control system includes the ability to save weld schedules to prevent unnecessary parameter input from part to part. The system is skid-mounted for ease of portability. The slide package and rotary table is integrated into a L-Arm configuration with a tilting axis to orientate from horizontal to vertical and any angle in between. The control cabinet and welding equipment are mounted to the base. The rotary table has a 25” 3-Jaw chuck for part holding.

This automated welding system provides improved production rates while maintaining a small manufacturing footprint. There are optimized deposition rates available for different applications.

VIDEO

Catalogs

ARC-05HVTe

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.