- Products

- Automatic cladding machine

- Arc Specialties

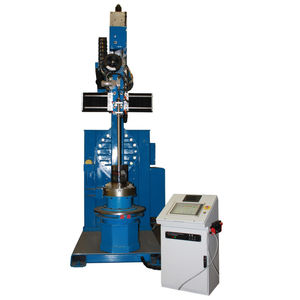

Automatic cladding machine ARC-05HV

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

HORIZONTAL VERTICAL CLADDING SYSTEM WITH ELBOW CAPABILITY

The ARC-05HV Cladding System has both vertical and horizontal welding capabilities which allows for a variety of welding applications. The system comes standard with two servo driven, 3-jaw chuck headstocks, and 60” cross slides to provide a quick transition between vertical and horizontal cladding set ups. A standard ARC 5 PLC control unit with touchscreen operator interface controls each set up. With the ARC-05HV, you vertical cladding system and your horizontal cladding system can occupy the same floor space and share the same operator interface.

Features:

Standard ARC 5 PLC control unit with touchscreen operator interface, weld schedule storage, 100% continuous AVC that maintains voltage while following the part, and teach & repeat programming of intersecting for automatic bore cladding.

Self-contained, skid mounted unit with up to 350 amp welding power supply, as well as a 150 amp hot wire power supply.

Horizontal overlay process doubles the deposition rate.

Heavy duty slides with up to 60” horizontal travel and 60” vertical travel.

Excellent system for quadrature, longitudinal, and transverse welding application.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.