- Products

- Automatic cladding machine

- Arc Specialties

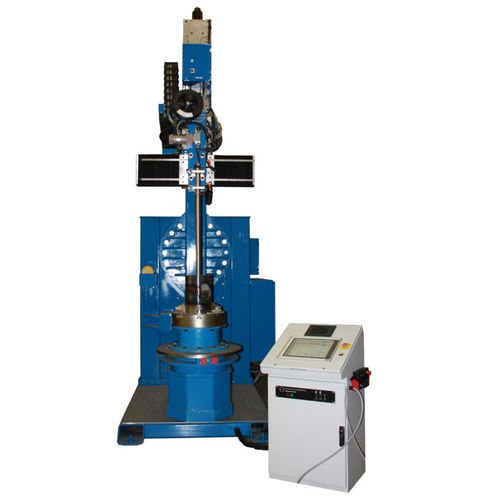

Automatic cladding machine ARC-05HVGT

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

BORE CLADDING SYSTEM

Newly-designed, innovative streamline ARC 5 control unit with weld schedule storage, tri-pulse capability, 100% continuous AVC that maintains voltage while following the part, and teach & repeat programming of intersecting bores for automatic bore cladding.

Self-contained, plate mounted unit with up to 500 amp welding power supply,, as well as a 150 amp hot wire power supply.

Tilting axis allows for manipulation with a tilt angle range from 0 to 90 degrees with the precision of 0.1 degree increments.

Horizontal tilt mode doubles the deposition rate.

Heavy duty slides with 24” horizontal travel and 42” vertical travel.

Multiple water cooled hot wire torch configurations from ⅞” OD to 1 ½” OD bodies and lengths of up to 3 feet with fixed angle or adjustable angle heads are available.

Standard 36” diameter X 6,000 lbs turntable with option of up to 48” diameter.

Manual slide for part loading. DC motorized automatic slide is available as an option.

Vision and Video Logging capabilities available as an option.

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.