- Products

- Automatic cladding machine

- Arc Specialties

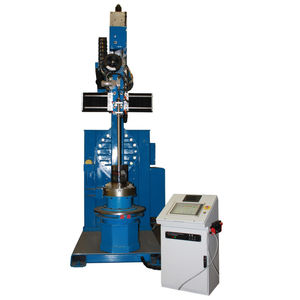

Automatic cladding machine ARC-05P

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

MANIPULATOR BORE CLADDING SYSTEM

Standard ARC-05P+ PLC control with touch screen operator interface, weld schedule storage, AVC, and teach and repeat programming of intersecting bores for automatic bore cladding.

Self-contained, plate mounted unit with manual rotary base, shelf mounted 300 amp welding power supply, as well as a 150 amp hot wire power supply.

Frame mounted safety switches (disconnects) for welding power supplies and electrical control to allow easy installation and relocation within your facility.

Heavy duty slides with 24” horizontal travel and 51” vertical travel (counter balanced).

Standard 36” diameter X 20,000 lbs turntable with option of up to 72” diameter x 40,000 lbs as well as built in slip ring connections for resistance heating while welding.

Multiple water cooled hot wire torch configurations from ⅞” OD to 1 ½” OD bodies and lengths of up to 6 feet with fixed angle or adjustable angle heads are available.

Full closed loop controls

Semi-automatic calibrations

RMS value calculations and display

Remote diagnostics via WiFi or ethernet connection

Multi-lingual capabilities

English to metric conversions

L-frame or manipulator configuration

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.