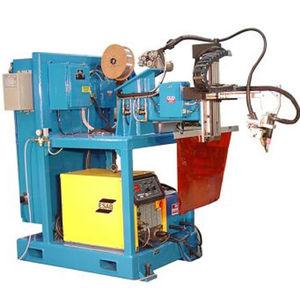

Arc welding system ARC-06BCNC

Add to favorites

Compare this product

Characteristics

- Technique

- arc

- Other characteristics

- CNC

Description

Capable of welding “journal bearings”, “thrust face”, “pin-O.D.”, and “ Pin end” welds.

Allows the programmer to control part manipulation, weld conditions, oscillation and arc length from a single program.

Real time display of position, weld conditions and system with real time observation (via remote camera) and position override capability.

Integrated Arc Voltage Control (ARC) unit provides adaptive control which maintains constant arc length over irregular parts.

Allows program control of all welding parameters including current, voltage, and powder feed rates.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogsRelated Searches

- Welding system

- Industrial robot

- Automatic welding system

- Articulated robot

- 6-axis robot

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Welding robot

- CNC welding system

- Steel welding system

- Cobot

- Pipe welding system

- Robotic welding system

- Vertical welding system

- Horizontal welding system

- 3-axis welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.