- Products

- Automatic cladding machine

- Arc Specialties

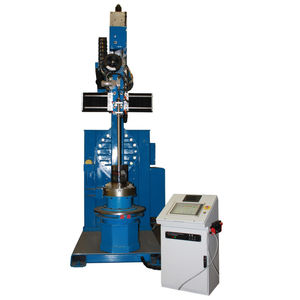

Automatic cladding machine ARC-06G

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

CNC GTAW BORE CLADDER SYSTEM

Rotary Torch Head servo controlled for continuous rotation.

Automatic Torch Centering Software.

Simplified operation including welding parameters, Torch position status, and English prompting for operator input.

Real time control of weld amps, weld volts, hotwire volts, and wire feed speed, integrated arc pulsing control, integrated Arc Voltage Control (AVC).

Capable of welding intersecting bores, race track configurations, seat pockets, ring grooves, upper and minor bores.

Column and Boom style manipulator equipped with servo motors, 96” vertical (Mast) travel (counter balanced), 60” horizontal (Boom) travel, 144” linear travel (Carriage), integrated cable track management system.

Integrated arc voltage control of Torch position including ramp and pulse lockout.

Remote diagnostics.

Data Logging Option.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.