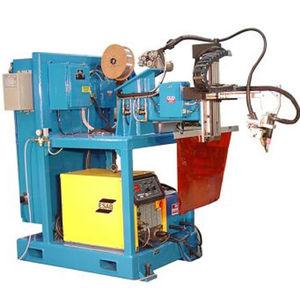

Submerged arc welding system ARC-06SverticalCNChorizontal

Add to favorites

Compare this product

Characteristics

- Technique

- submerged arc

- Other characteristics

- vertical, CNC, horizontal

Description

CNC SAW BOP WELDING SYSTEM

PMAC CNC controller

4-axis fully-automated coordinated motion

Cross slides with 94” vertical travel and 72” horizontal travel

Cross slide mast on servo linear travel carriage with 120” linear travel

Integration of tilt & rotate positioner

Fully integrated, PC-based HMI with welding parameter feedback including display of slide & table position

HMI pendant with remote control

G-code programmable

Automated G-code program generation based on part dimensions

Automates scratch starts for reduced operator intervention

Constant surface speed welding using inverse kinematics

ACC torch height control

Torch position teach function

Welding parameter storage

Roller head submerged arc welding torch

1000 amp PowerWave 1000 AC/DC power supply

Automated flux delivery from 300 lb pressure-fed flux tank

Flux hopper with vacuum recovery (Heated flux option available)

VIDEO

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogsRelated Searches

- Welding system

- Industrial robot

- Automatic welding system

- Articulated robot

- 6-axis robot

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Welding robot

- CNC welding system

- Steel welding system

- Cobot

- Pipe welding system

- Robotic welding system

- Vertical welding system

- Horizontal welding system

- 3-axis welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.