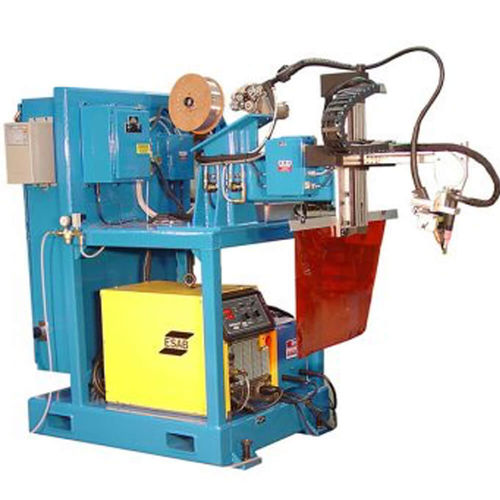

Arc welding system ARC-10G automaticmanualprecision

Add to favorites

Compare this product

Characteristics

- Technique

- arc

- Operational mode

- automatic, manual

- Other characteristics

- precision

Description

PLC GTAW

Computer Controlled Cross Slides

Integrated Oscillator

PLC Control of motion, program steps, and welding parameters

Storage of 99 welding and oscillation schedules ( password protected)

Storage of 10 programs with 20 steps each

Real-time overrides of weld amperage, weld volts, wire feed rate, and oscillation width

Manual or Automatic ARC Voltage Control (AVC)

Precision stepper motor drive cross slides for oscillation and torch position

2 user-defined inputs and outputs

User control of the welding process including continuous and pulse welding modes

Simple touch screen user interface for entering data, programming, and general

Simplified operation including default-welding parameters, Torch position teach function, and English prompting for operator input

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogsRelated Searches

- Welding system

- Industrial robot

- Automatic welding system

- Articulated robot

- 6-axis robot

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Welding robot

- CNC welding system

- Steel welding system

- Cobot

- Pipe welding system

- Robotic welding system

- Vertical welding system

- Horizontal welding system

- 3-axis welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.