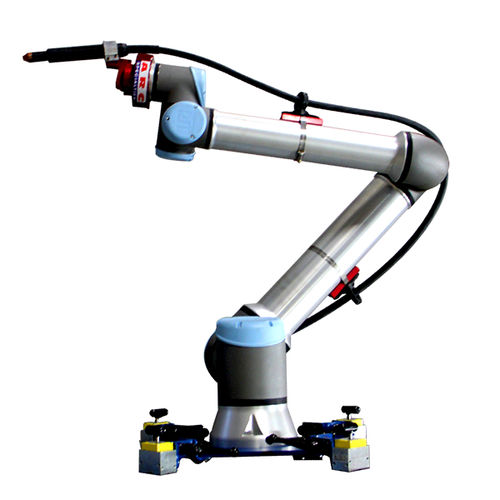

Cobot SnapCut 6-axiscuttingfloor-mounted

Add to favorites

Compare this product

Characteristics

- Type

- collaborative

- Number of axes

- 6-axis

- Function

- cutting

- Mounting

- floor-mounted

Description

SnapCut allows non-welders and non-robot operators the ability to cut shapes into three-dimensional, structural-steel components easily.

SnapCut utilizes the UR collaborative robot to manipulate a Hypertherm cutting torch to the desired positions around the cutting path. Included in the SnapCut software are standard shapes like squares, rectangles, circles, or C-channels that can be selected for parametric programming. The operator will simply move the cutting torch to a few locations on the cutting surface, hit run, and watch the sparks fly. If you need a non-standard shape, you can program it yourself and insert the SnapCut instructions for cutting control or have Arc Specialties add the shape to the parametric programming interface.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Arc Specialties‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.