- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

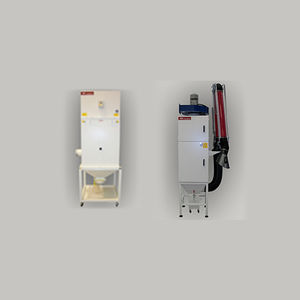

Smoke mist collector ARIS seriesfiltration mediamachine-mount

Add to favorites

Compare this product

Characteristics

- Application

- smoke

- Type

- filtration media

- Other characteristics

- machine-mount

- Flow rate

2,000 m³/h, 3,500 m³/h, 4,000 m³/h, 6,000 m³/h

(70,629 ft³/h, 123,601 ft³/h, 141,259 ft³/h, 211,888 ft³/h)

Description

The new ARIS series is ideal for applications which require high air flows and filter stages capable of re-condensing and retaining large amounts of oily mist and fumes.

The world of machine tools is in continuous evolution, machines are ever more high performance – and more polluting. The new ARIS series is ideal for applications which require high air flows and filter stages capable of re-condensing and retaining large amounts of oily mist and fumes. It can also be used for extracting non-explosive powders generated during brushing or finishing or materials with residue of abrasive paste. It has a vast range of applications which covers nearly all mechanical engineering applications, both dry and wet.

Thanks to its high performance, the ARIS series is ideal for the semi-centralisation of multiple machine tools with the same characteristics.

The new ARIS series is composed of 4 models with air flow rates of 2000 to 6000 m3/h, suited to purifying particles of variable size with interchangeable filters of different filtration efficiencies.

Each purifier is equipped with a high (EPA) and very high (HEPA) efficiency filter stage, compliant with EN 1822, and suited for reducing micro-dust, micro-mist and fumes.

The units are equipped with low energy consumption motors rated class IE3 and motor thermal cutouts.

They are fitted with a drain system for recovering the condensed fluid.

– SELF-SUPPORTING ARTICULATED BOOM

– ACTIVE CHARCOAL CELL FOR REDUCING ANY EXHALATIONS AND ODOURS

– NOISE ATTENUATOR

– ELECTRONIC DEVICE TO MONITOR FILTER CONDITIONS

Catalogs

ARIS series

1 Pages

AR FILTRAZIONI Catalog

8 Pages

Related Searches

- Dust collector

- Industrial fume extractor

- Mobile fume extractor

- Filter industrial dust collector

- Fume extractor with extraction arm

- Mist extractor

- Oil mist extractor

- Compact industrial dust collector

- Mobile industrial dust collector

- Laser fume extractor

- Fume extractor with HEPA filter

- High-efficiency dust collector

- Self-cleaning industrial dust collector

- Filtration media mist extractor

- Modular industrial dust collector

- Machine tool mist collector

- Compact mist extractor

- Powder coating dust collector

- Smoke mist collector

- Heavy-duty dust collector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.