- Machine-tools

- Finishing Machine

- Cutting deburring machine

- ARKU Maschinenbau GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

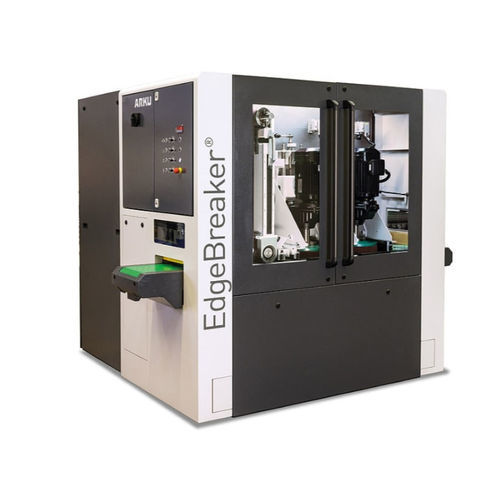

Cutting deburring machine EdgeBreaker® 1000punchingedge roundingdeburring

Add to favorites

Compare this product

Characteristics

- Associated function

- edge rounding, deburring, finishing, cutting, punching

- Type

- brush

- Applications

- metal parts, for small parts

- Other characteristics

- automatic, compact, dry

- Working width

250 mm

(9.84 in)

Description

The deburring machine for single-sided deburring, edge rounding and surface finishing small sheet metal parts after laser cutting and punching.

Cost-effectively deburr, edge round and surface finish small sheet metal parts after laser cutting and punching thanks to the single-sided EdgeBreaker® 1000 deburring machine. This machine is a plug and play concept since it has a wet dust extraction system already built in, allowing you to process all metal alloys safely. The result is a well-thought-out machine concept which is easy to use, with high flexibility and outstanding performance.

Single-sided deburring, edge rounding, and surface finishing of small parts cut from sheet metals are crucial processes in various industries like automotive, aerospace, electronics, and manufacturing. ARKU‘s deburring machines process sheet metal parts that meet quality standards, have safe edges, and provide better performance. Discover the versatility of the EdgeBreaker® 1000 and benefit from its high flexibility and user-friendliness. Contact us our expects today to explore solutions tailored to your specific needs.

Your Advantages as an Overview

Deburring with the smallest space requirement.

Thanks to the compact design of the EdgeBreaker® 1000 and the integrated wet dust extraction system, you save valuable manufacturing floor space. The machine can easily be integrated into existing production lines while still offering outstanding performance. Regardless of whether you want to deburr small sheet metal parts, round them, or apply a surface finish, the EdgeBreaker® 1000 is the ideal machine.

Catalogs

No catalogs are available for this product.

See all of ARKU Maschinenbau GmbH‘s catalogsOther ARKU Maschinenbau GmbH products

Reliable Deburring & Edge Rounding Machines

Related Searches

- ARKU deburring machine

- Metal parts deburring machine

- ARKU automatic deburring machine

- Brush roller deburring machine

- ARKU edge rounding deburring machine

- ARKU deburring deburring machine

- Abrasive belt

- Finishing deburring machine

- ARKU sheet metal deburring machine

- Belt deburring machine

- Compact deburring machine

- Grinding deburring machine

- Double-sided deburring machine

- Small part deburring machine

- Stationary deburring machine

- ARKU cutting deburring machine

- Metal abrasive belt

- Punching deburring machine

- Finishing abrasive belt

- Deslagging deburring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.