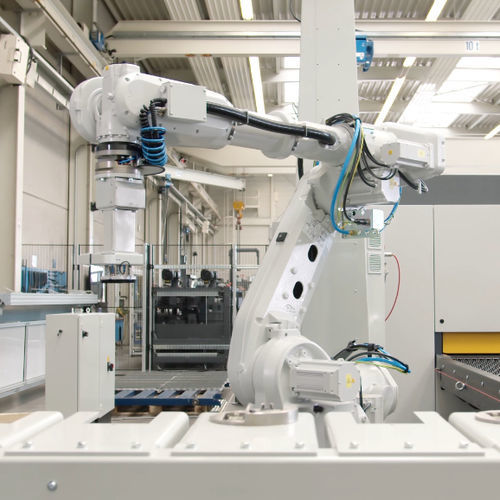

Parts handling from ARKU: the ideal connection between automated deburring and automated loading and unloading of parts. All thanks to our state-of-the-art vision robot for material handling.

Manual work takes up too much time! This also applies to deburring, which is why you can increase your efficiency and throughput with an automated deburring machine. You can for even further with robots that take care of the loading and unloading of deburring machines. Whether thin sheet metal parts or heavy metal plate. This activity is monotonous, time consuming and - especially with heavy metal plate - strenuous for humans. In addition, there are more meaningful tasks for qualified employees elsewhere in the company. A robot for parts handling is therefore an ideal addition to the deburring machine. Thanks to automatic part recognition, modern vision robots do not even require separate robot programming. This make them particularly easily to set up and switch between different materials.

Advantages

No need for manual lifting or turning of heavy parts

Constantly lifting and placing sheet metal and heavy metal parts is not a pleasant task for most people. The physical stain is particularly high with heavy plate. However, these repetitive tasks are ideal for a robot.

Small batch sizes become profitable

Nowadays, robots can perform tasks independently without the need for complex programming. This is possible thanks to cameras and artificial intelligence (AI).