- Products

- NdFeB magnet

- Arnold Magnetic Technologies

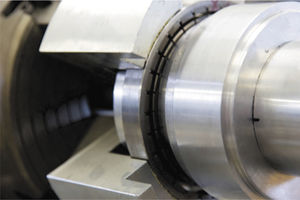

NdFeB permanent magnet N series cylindricalrectangulararc

Add to favorites

Compare this product

Characteristics

- Material

- NdFeB

- Configuration

- cylindrical, rectangular, arc

- Applications

- for motors, for sensors

Description

Neodymium iron boron (NdFeB), or “neo” magnets offer the highest energy product of any material today and are available in a wide range of shapes, sizes and grades. Neo magnets can be found in a variety of applications including high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors and loudspeakers.

Magnetic properties will differ depending upon alignment direction during compaction and upon size and shape. Download individual spec sheets from the table below, or get the full neo catalog for specific grades and their magnetic properties, including the trade-off in Br (and energy product) for HcJ (intrinsic coercivity, resistance to demagnetization). For GBD Neo Grades, see below.

MAXIMUM USE TEMPERATURE AND CORROSION

Determining whether or not to use neo magnets instead of our RECOMA® SmCo magnets, for example, is a function of the maximum temperature of the application, required magnetic output at typical use temperature and total cost of the system.

Neo magnets have some limitations due to their corrosive behavior. In humid applications, a protective coating is highly recommended. Coatings which have been used successfully include epoxy coating, nickel plating and combinations of these coatings. Arnold also has the capability to apply Parylene coating to neo magnets. Effectiveness of coating is dependent upon the quality of the base material. Arnold has evaluated multiple manufacturers for corrosion resistance of the base material and only supplies licensed, highly corrosion-resistant materials produced under tight control.

Catalogs

No catalogs are available for this product.

See all of Arnold Magnetic Technologies‘s catalogsOther Arnold Magnetic Technologies products

PERMANENT MAGNETS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.