Can loading and unloading system for tubesautomatic

Add to favorites

Compare this product

Characteristics

- Product applications

- for cans, for tubes

- Other characteristics

- automatic

Description

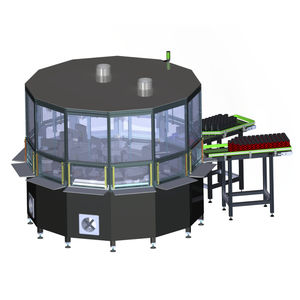

Automated loading and unloading of cans for RP/2RP series

• Optional automated loading system replaces manual loading

• Components include:

• Inbound conveyor

• Outbound conveyor

• Manipulator

• Programmable Logic Controller (PLC)

• Manipulator uses a combination of pneumatic and electrical actuators

• Can or tube separator

• Placement system automatically inserts unprinted product into the thorn

• Pick-up system automatically removes printed product from the thorn

Plasma surface treatment

• All mechanical and electrical parts included

• Two nozzle systems

• Installation

• Compressed air required

Flammbing treatment

• All mechanical and electrical parts included

• Nozzle system

• Installation

• Natural gas or LPG connection required

AXPO9-KP active filtration unit with regulation

• For use with KP series printers

• Electronic regulation by frequency changer

• First set of filtration capsules included

Mechanical holders for cylindrical or conical objects in RP & 2RP series printers

• One adaptor is required for each product size

• Manual exchange of holders required

• Holders exchanged by loosening two screws

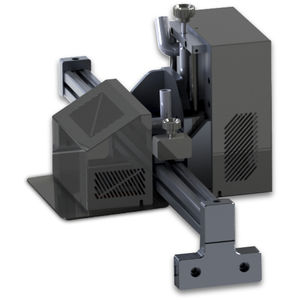

Automated holders for cylindrical or conical objects in RP & 2RP series printers

• Fully automated to manage various product sizes be printed in a printing run

• Size adjustment made only to the first product to be printed in a printing run

• Electronically adjustable in 2-axis

• Maximum movement diameter: 150 mm

• Maximum movement length: 200 mm

Extra quiet air compressor

• Useful in public spaces to reduce noise (exhibitions, etc.)

• Noise level: 45 – 47 dB

• Maximum pressure: 8 bar

• Volume: 200 l/min

Catalogs

No catalogs are available for this product.

See all of Arojaxorfex‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.