- Packing - Handling - Logistics

- Packing and Packaging

- Pressure capping machine

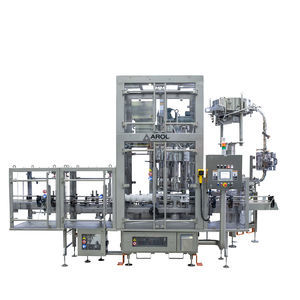

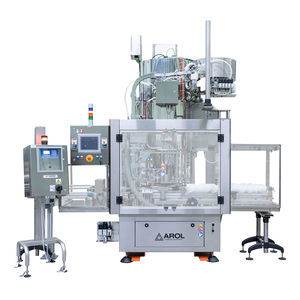

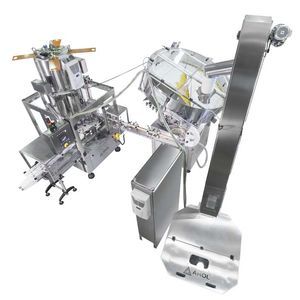

- AROL Closure systems

Pressure capping machine EAGLE PPpress-onautomaticbottle

Add to favorites

Compare this product

Characteristics

- Type

- pressure, press-on

- Operating mode

- automatic

- Product applications

- bottle

- Application field

- for the chemical industry, for the beverage industry

- Throughput

Min.: 50 p/min

Max.: 50 p/min

Description

SINGLE HEAD CAPPING MACHINE

APPLICATION

Press-on over caps

Press-on cover for cans

Flex spout

Press-on flip top caps

Plastic insert

Pressure cover

T caps

Press-on caps

Flex spout

Plastic caps with pourer - non refillable

Spoon

Aerosol caps

Press-on irregular geometry caps

SPEED PRODUCTION: up to 50 bpm - 3.000 bph

CLOSURE HEADS: closure chuck with vacuum - closure chuck - gripper

EXECUTION

• STANDARD: structure with painted steel components. not washable

• INOX EXTERNAL SURFACES (I.E.S.): external stainless steel components. Suitable for washing of the capping zone

• WASHABLE (UPON REQUEST): stainless steel components. complete washing of the capper is possible (thanks to gaskets and labyrinths)

OPTIONS

• On caps chute: overturned caps automatic ejector (A.E.D.) - ionizer/dust extraction - uv lamp

• Quick change format: sorter (manual or automatic) - caps chute (toolless std execution) - body-guide assembly (toolless std execution) - ending terminal

• Others: motorized height adjustment - caps elevator - additional vibrating tank - machine with motorized bottle conveyor - machine on wheels - machine in lowered execution

Catalogs

CLOSYS EAGLE PP

4 Pages

Related Searches

- Automatic capper

- Bottle capper

- Screw capping machine

- Capper for the food industry

- Automatic screw capping machine

- Rotary capper

- Bottle screw capping machine

- Capper for the beverage industry

- Capper for the pharmaceutical industry

- Linear capper

- Capper for the chemical industry

- Screw capping machine for the food industry

- Screw capping machine for the chemical industry

- Screw capping machine for the pharmaceutical industry

- Twist-off cap capper

- Pressure capper

- Screw capping machine for the beverage industry

- Rotary screw capping machine

- Multi-head capper

- Beverage capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.