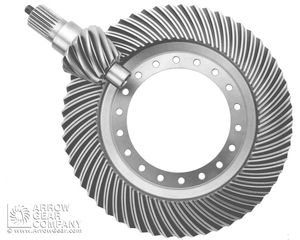

Helical gear hub

Add to favorites

Compare this product

Characteristics

- Teeth

- helical

- Configuration

- hub

Description

Rounding out a full range of gear manufacturing capabilities, Arrow is equipped for the manufacture of helical gears.

Unlike spur gears, which feature teeth that are parallel to the axis of the gear, helical gears have teeth that are cut at an angle. During the engagement of the teeth, contact begins at one end of the tooth, and then spreads gradually throughout rotation, until full mesh is achieved. The teeth of the helical gears then gradually exit mesh in the same manner.

The benefit of helical gears is that this gradual engagement results in smoother and quieter gear operation, as compared to spur gears.

Arrows size range and capabilities for Helical Gears are provided in the list below.

Helical gear teeth in mesh

Maximum Pitch Diameter 36

Diametral Pitch 3.0 48

Face Width 13.0

Unground Tooth AGMA Q9

Ground Tooth AGMA Q13

Catalogs

No catalogs are available for this product.

See all of Arrow Gear Company‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.