O-ring seal RSO seriesroundpolyurethaneNBR

Add to favorites

Compare this product

Characteristics

- Type

- O-ring

- Configuration

- round

- Material

- polyurethane, NBR, PTFE

- Application

- profile, cutting

- Fluid

- for mineral oil

- Other characteristics

- dynamic, abrasion-resistant

- Temperature limit

Max.: 110 °C

(230 °F)Min.: -35 °C

(-31 °F)- Pressure limit

250 bar

(3,625.9 psi)- Diameter

Max.: 200 mm

(7.874 in)Min.: 12 mm

(0.472 in)- Outer diameter

Max.: 221 mm

(8.701 in)Min.: 19.5 mm

(0.768 in)- Shore A hardness

93 unit

- Speed

0.5 m/s

(1.6 ft/s)

Description

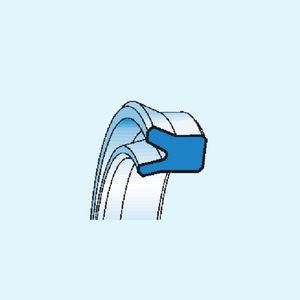

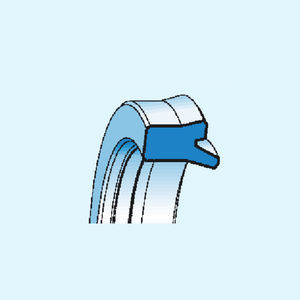

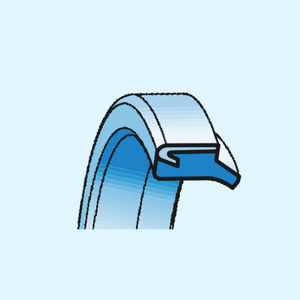

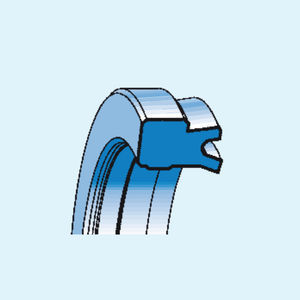

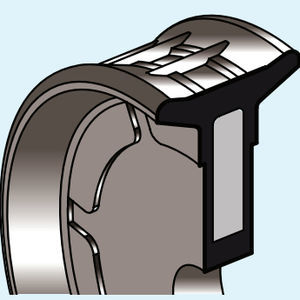

The RSO seal type has been developed to replace or work jointly with stepseals in PTFE, because of the same groove dimension.

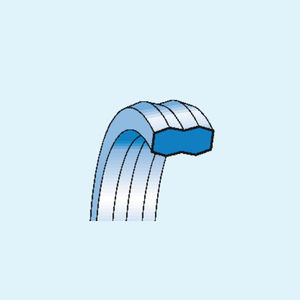

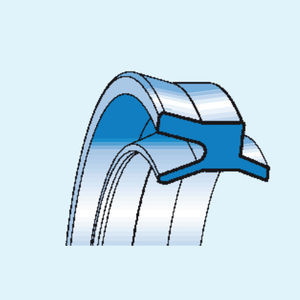

Internally it has a round groove where an O-ring can be inserted and housed. The O-Ring acts as

energizer for the static and dynamic sealing lips even without pressure.

This profile has also excellent results at very low speed and pressure, because of the low friction.

The machining of the groove is easier thanks to the reduced axial dimension.

The proposed material is a “C0” type polyurethane, with high elasticity modulus, low compression-set

and high abrasion resistance.

O-ring in NBR 70 (N0).

As for all seal housings, remove any flash or cutting edges.

For further information please refer to the installation instructions on page 26.

Catalogs

RSO

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.