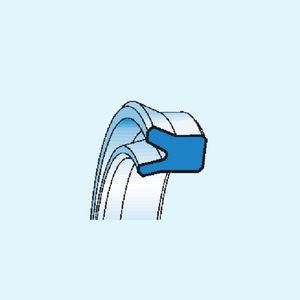

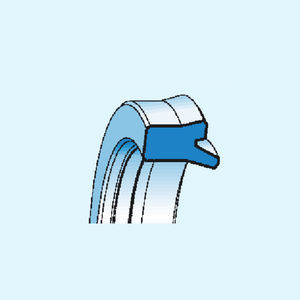

Lip seal RBR seriesroundVpolyurethane

Add to favorites

Compare this product

Characteristics

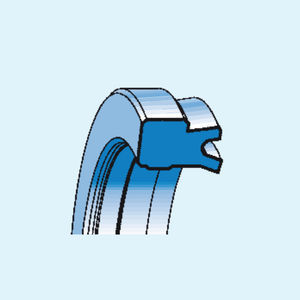

- Type

- lip

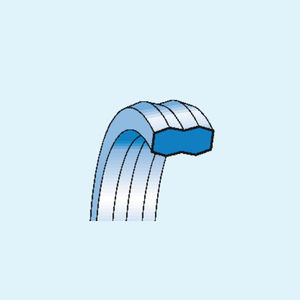

- Configuration

- round, V

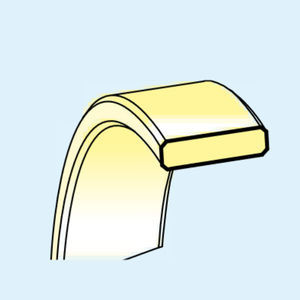

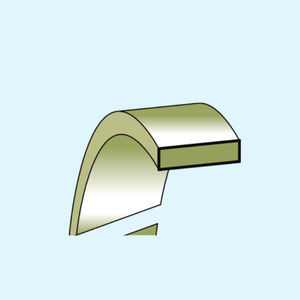

- Material

- polyurethane, resin

- Application

- profile, cylinder

- Fluid

- for mineral oil

- Other characteristics

- anti-extrusion

- Temperature limit

Max.: 110 °C

(230 °F)Min.: -35 °C

(-31 °F)- Pressure limit

400 bar

(5,801.5 psi)- Diameter

Max.: 200 mm

(7.874 in)Min.: 45 mm

(1.772 in)- Outer diameter

Max.: 220.5 mm

(8.681 in)Min.: 60.5 mm

(2.382 in)- Shore A hardness

93 unit

- Speed

0.8 m/s

(2.6 ft/s)

Description

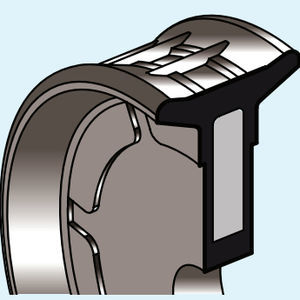

The RBR ring, working as buffer ring, has been specially designed to work as main seal, to be used

in combination with asymmetrical lip seals (see RSA, page 30).

Its function is to maintain working pressure for the second seal. It does not provide full sealing effect so an oil chamber will thus form between the two seals.

Thanks to the special profile of the RBR ring, the growing pressure in the space will be released into

the cylinder once a certain value is achieved. It works as a valve.

It has been also designed to compensate pressure peaks.

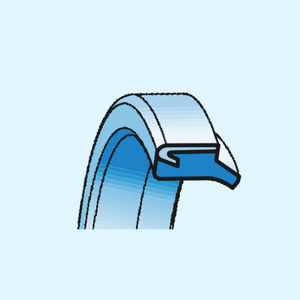

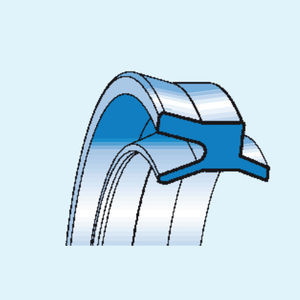

The proposed material is a “C0” type polyurethane, with high elasticity modulus, fundamental for the

sealing, low compression-set and high abrasion resistance.

For the anti-extrusion ring we propose a polyacetalic resin (R0) with high tensile strength.

Compound reference: CR

The assembling is done in closed groove. The polyurethane seal must therefore be fitted before the

anti-extrusion ring.

Catalogs

RBR

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.