Piston wear ring HIS rodmetal

Add to favorites

Compare this product

Characteristics

- Type

- piston, rod

- Material

- metal

Description

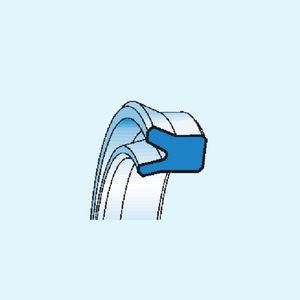

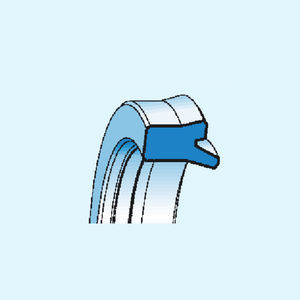

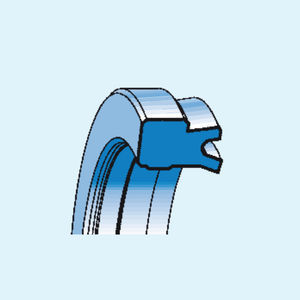

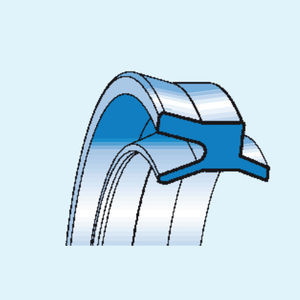

The HIS wear rings have been developed in order to keep all the parts of the cylinder aligned (the rod

with the head, the piston with the bore). They play an important role as they help the rod

seal, the wiper and the piston seal working without any misalignments and at the same time they

prevent any contact between the metal parts. The material, which has a very low friction factor, does

not cause load losses (linearity).

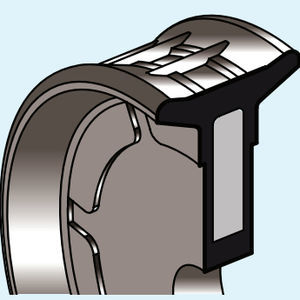

It endures deformations under heavy loads, as the softening point is close to the fusion point (it works

at 115° C ). For an easier choice of the piston or rod guide, we suggest the use of this formula to find the

wear ring length.

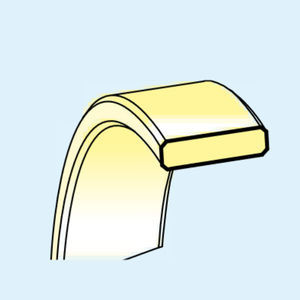

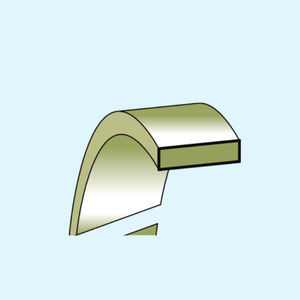

Material

The material is a polyacetalic resin reinforced with fibreglass.

For working temperatures higher than 115° C, the material is a reinforced polyamidic resin.

Compound reference for temp 115° C: R1

Assembling

The assembling can be easily done since the wear ring is cut and extremely elastic.

The chamfers on both sides have been studied to better insert the wear ring in the rod.

Catalogs

No catalogs are available for this product.

See all of ARTIC SEALS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.