- Metrology - Laboratory

- Metrology and Test Equipment

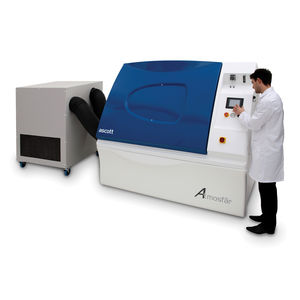

- Corrosion test chamber

- Ascott Analytical Equipment

Salt spray corrosion test chamber S seriescanopy

Add to favorites

Compare this product

Characteristics

- Test type

- salt spray corrosion

- Configuration

- canopy

- Capacity

Min.: 120 l

(32 gal)Max.: 2,600 l

(687 gal)- Temperature

Min.: 18 °C

(64 °F)Max.: 70 °C

(158 °F)- Length

Min.: 490 mm

(19.29 in)Max.: 1,500 mm

(59.06 in)- Width

Min.: 715 mm

(28.1 in)Max.: 2,160 mm

(85 in)- Depth

Min.: 490 mm

(19 in)Max.: 980 mm

(39 in)

Description

Ascott salt spray cabinets and chambers – one of the world’s most modern and most versatile salt spray corrosion test systems – and with design, ergonomics and quality that’s in a class of its own.

Chambers to cover every testing requirement from continuous salt spray test through to condensation humidity and modified tests.

Two specification levels:

Standard

Standard models meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS) or Cupric Acid (CASS).

Premium

Premium models can perform the same basic salt spray tests, but in addition are equipped with extra features which enable them to undertake ‘modified’ tests such as those defined in ASTM G85. Here conventional salt spray is often combined with one other climate, in a two-part cycle, to accelerate the test. For example: salt spray and condensation humidity (SWAAT) or salt spray and drying (PROHESION) or salt spray and SO2 testing.

All Ascott corrosion test chamber models feature:

Low loading threshold for ergonomic loading and unloading.

‘Easy Open’ pneumatically operated canopy, with safety interlock.

Dry seal gasket to prevent wetting the operator’s clothes.

Timed canopy lock and purge of the cabinet interior with fresh air after testing and before the chamber is opened.

Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance.

VIDEO

Catalogs

Salt Spray Test Chamber

12 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.