- Metrology - Laboratory

- Metrology and Test Equipment

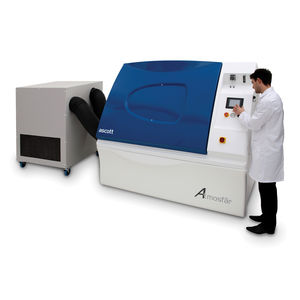

- Corrosion test chamber

- Ascott Analytical Equipment

Corrosion test chamber Kesternich on castersverticalautomatic

Add to favorites

Compare this product

Characteristics

- Test type

- corrosion

- Configuration

- on casters, vertical

- Other characteristics

- automatic

Description

KH300 – Fully Automatic, SO2 Gas Dosing Test Chamber

Kesternich testing simulates acid rain or industrial chemical exposure to evaluate the relative corrosion resistance of the coating, substrate, or part itself. Parts or panels are placed inside a specially designed chamber and are exposed to SO2 and condensation humidity before being evaluated for resistance to corrosion.

Ascott Kesternich Chamber

Fully Automatic, electronic gas dosing Kesternich Test Chamber – 300L

A specific volume of SO2 gas, usually 0.2L, 1L or 2L is introduced into the test chamber, the chamber temperature is increased to a predetermined level and the relative humidity is maintained at condensation levels. After a set period, the chamber is vented and the temperature is allowed to decrease to ambient conditions.

Ascott’s Kesternich chamber does not require any human intervention whilst running the tests, its fully automatic design is controlled by a state of the art control system. The Kesternich chamber is designed to meet various gas dosing test standards as listed below and can also be used as a condensation humidity chamber.

Meets standards:

ASTM D2247,

ISO 11503,

NFT 30-077,

NFT 30-055,

ASTM G87,

BS3900/F9,

ISO 6270-2

EN ISO 6988,

ISO EN 1096 B & C

DIN 50017

ISO 3231,

DIN 50018,

VDA 621-421,

ISO 22479,

Catalogs

No catalogs are available for this product.

See all of Ascott Analytical Equipment‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.