- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Hand-held demagnetizer EDH 123for workpiecesmanual

Add to favorites

Compare this product

Characteristics

- Configuration

- hand-held

- Product handled

- for workpieces

- Other characteristics

- manual

Description

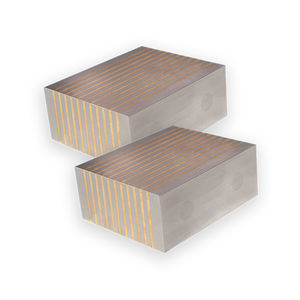

ENTMAG demagentizing plates are a simple and cost-effective solution for the demagnetization of single and series parts of small and medium size. The devices demagnetize up to a maximum distance of 60 mm. The work pieces are demagnetized either as single units fed by hand or conveyor. Clusters are to be avoided.

Applications

- Neutralization of interfering residual magnetism.

- Demagnetizing is terminated after leaving the plate at a distance of appr. 300 mm.

Features

- Robust, humidity-proof design (V2A-case).

- Suitable for work pieces made of soft and medium-hard material. High-grade hardened,

intricate parts are recommended to be tried out before.

- All operating voltages at 50Hz or 60Hz are deliverable (lower frequency or pulse

recurrence frequency for problematic cases).

- Connecting line, 2 m long, with plug connector.

- Type 17 designed for incorporation in belt conveyors (flow-line production).

- Conveying rate for demagnetizing <0.5 m/s

- Demagnetization can penetrate deeper than 0.5 mT (5 Gauss). Test: Iron filings must not

adhere on the work piece.

Catalogs

Magnetic Tools

36 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.