- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

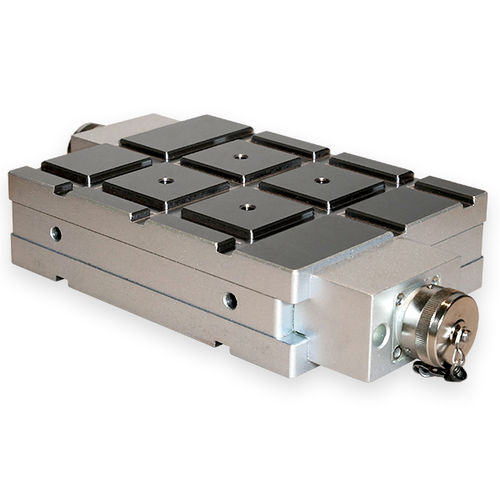

Double-face magnetic chuck Doublemag | Triplemagelectro-permanent with square polesfor millingfor machine tools

Add to favorites

Compare this product

Characteristics

- Technology

- electro-permanent with square poles

- Type

- double-face

- Applications

- for milling, for machine tools, for drilling

Description

The Doublemag are small Magnaslots, but magnetized on top (to hold the workpiece) and on bottom (to hold itself on the machine table). They are very handisome and flexible in use. They can be combined in multiple number to a large magnetic table to clamp economically large workpieces.

The Triplemag are same as Doublemag, but have additional and separately switched magnets on bottom side, enabling a wanted position on the machine table or the wall before clamping the job. These magnets are manufactured as double row (DM502 or TM508) or single row (TM505).

Application:

- Clamping big or bulky workpieces for milling

- Clamping for edge cutting or deburring

- For simple and fast fixing of workpieces

- Also usable with fixed and movable pole extensions for uneven surfaces

Professional advantages:

- Drastic reduction of set-up times

- 5-side machining with simple and fast positioning and clamping

- Less stress, less vibrations, less torsions for better machining

- Flexible combination of multiple magnets to machine large or bulky workpieces

- Better accuracy-plane-parallelism 0,01/1000mm is reachable

- The advantage of fixed and mobile pole extensions for balancing uneven, bent, large workpieces

Features:

- Pole size 50 × 50 mm

- Adhesive force up to 400 kg/Pol

- Full clamping force will only be achieve if the supporting table is ferromagnetic and at least 15 mm thick

- Penetration depth of the magnetic field up to 12 mm

- Patented solid top resists best to hot chips and coolance and cares also for heat dissipation

Catalogs

No catalogs are available for this product.

See all of Assfalg GmbH‘s catalogsRelated Searches

- Magnetic chuck

- Grinding magnetic chuck

- Rectangular magnetic chuck

- Electro-permanent magnetic chuck

- Permanent magnet magnetic chuck

- Machine tool magnetic chuck

- Milling magnetic chuck

- Sine table magnetic chuck

- Circular magnetic chuck

- Round magnetic chuck

- Manual magnetic chuck

- Drilling magnetic chuck

- Large part magnetic chuck

- Magnetic block

- Radial magnetic chuck

- Machine magnetic chuck

- Permanent magnetic block

- Welding magnetic chuck

- Magnetic chuck with T-slots

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.