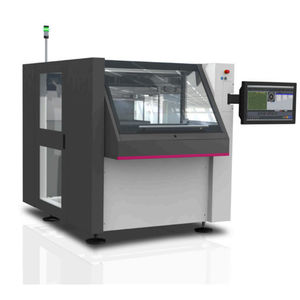

Plastic cutting machine DIVISIO 2000/2100/2300for printed circuit boardsservo-drivenfor the electronics industry

Add to favorites

Compare this product

Characteristics

- Material

- for plastics

- Product handled

- for printed circuit boards

- Control type

- servo-driven

- Applications

- for the electronics industry

- Other characteristics

- semi-automatic, linear

Description

Description

The DIVISIO 2000 is a semi-automatic system for stress-free

depaneling of PCBs. The X- and the Y-axes are both equipped

with highly dynamic linear motor technology, the Z-axis is servo-driven. Already existing product carrier adapters can easily

be used with this machine. The vacuum system is optimized

with the help of the Tornado-Effect.

The system offers a cost-efficient solution for customers who

wish to depanel stress-free but who do not produce such a

high volume to justify the acquisition of an inline machine.

By positioning the routing axis either above or below the

electrically driven rotary table the DIVISIO 2100 has the

flexibility to represent a verified production process. It can

therefore be used without any restrictions as back-up for the

inline production.

The DIVISIO 2300 commands the largest working area within

the entire DIVISIO depaneling systems.

Features

_X- and Y-axis with high-end linear motors

_Z-axis servo-motor-driven

_Rotary-table with two working areas

_Touch screen monitor

_HMI offers comfortable operation

_Ionization unit

_Automatic tool change with 2 routers per magazine

_Complete tool management

+ Breakage control

+ Length verification

+ Diameter check

+ Life span monitoring

+ Dynamic utilization of full router bit

_ Automatic maintenance schedule

Catalogs

DIVISIO 2000/2100/2300

2 Pages

DIVISIO 2000 Series

2 Pages

Related Searches

- Cutting system

- CNC cutting system

- Automatic cutting system

- Knife cutting system

- High-speed cutting system

- Plastic cutting system

- Cutting machine for the electronics industry

- Linear cutting system

- Modular cutting system

- Servo-driven cutting system

- Semi-automatic cut-off machine

- Printed circuit board cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.