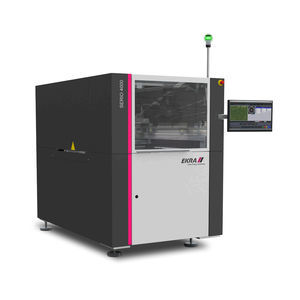

Automatic stencil printer HYCON XH3Dsolder pasteSMT

Add to favorites

Compare this product

Characteristics

- Control

- automatic

- Number of colors

- solder paste

- Applications

- SMT

Description

Component printing with 3D Technology

The 3D screen printing system “XH3D“, a machine type out of EKRA´s unique 3D Printer platform. By using stencil- or screen technology, it generates complex 3D structures on an base plate.

According to the actual printed layer height, the machine adjusts automatically the snap off distance.

Optionally the machine communicates with the patented screen exchange unit. The capacity of the unit allows to store up to 10 screens.

The base plate for the 3D compenent print, can be fixed by vacuum, direct at the movable print table. An optional drying system can be placed beside the machine to cure the actual layer.

Features

_ Automatic snap of setting according to the printed layer

_ Alignmment accuracy +/-10 µm@ 6 sigma

_ Dedicated vacuum table

Options

_ Screen Exchange Unit

_ Curing, IR or UV Unit

_ 3D Measurement System, for precise snap off setting

_ Different dispensing types

_ Motorized Squeege head

_ Stencil Cleaning System iROCS

Catalogs

HYCON XH3D

2 Pages

Related Searches

- Marking machine

- Automatic labelling machine

- Laser marking workstation

- Printing machine

- Stencil printer

- Automated marking machine

- Compact marking workstation

- Automatic stencil printer

- CO2 laser marking machine

- Automatic label printer-applicator

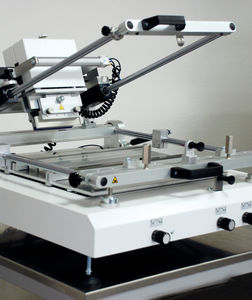

- Flat bed stencil printer

- Inkjet printing machine

- Printed circuit marking machine

- Electronic stencil printer

- SMT stencil printer

- Solder paste stencil printer

- Semi-automatic stencil printer

- Desktop stencil printer

- Marking and verification system

- Wafer printing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.