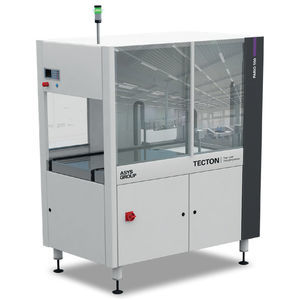

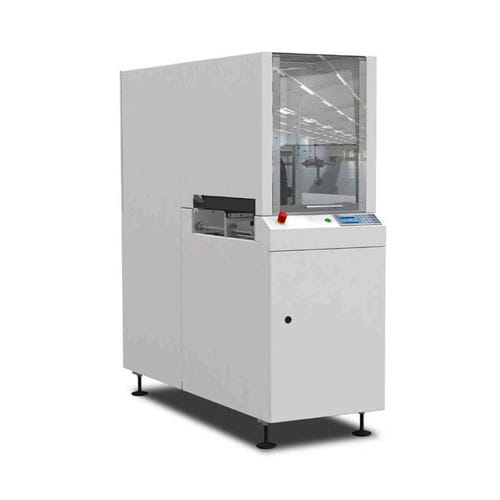

Compressed air cleaning system VEGO ACS 01PCBhigh-frequency

Add to favorites

Compare this product

Characteristics

- Technology

- compressed air

- Applications

- PCB

- Other characteristics

- high-frequency

Description

Description

The system is used for contactless antistatic cleaning of unpopulated printed circuit boards. During the transfer of the PCB, dust particles on the surface are dissolved by ionized air using compressed air-supported flat jet nozzles and sucked upwards. The cleaned and neutralized board is then transferred to the downstream stencil printer. The intelligent electrostatic discharge through high-frequency technology ensures optimum discharge performance.

Features

_ Cleaning from the top

_ Rest charge (Ion balance) < +/- 35V, conform to Norm IEC 61340-5-1:2016

_ Integrated exhaust system with compact filter

_ Monitoring of:

_ Filter contamination

_ Function and contamination of ionization

_ Air supply

_ Manual width adjustment with clamping lever

_ Support edge 3mm

_ Conveyor speed control

_ ESD transport belt

_ Dust cover

Options

_ Electrical width adjustment

_ Automatic width adjustment

_ Cleaning from the top with rotary nozzles (Taifun-Clean)

_ Cleaning from the bottom with rotary nozzles

(Taifun-Clean)

_ Additional manual or motorized X-Y- Scanner

axis from the top1)

_ Additional manual or motorized X-Y- Scanner

axis from the bottom2)

_ 2-color LED-Signal light + buzzer

Catalogs

No catalogs are available for this product.

See all of ASYS GROUP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.