- Hydraulics - Pneumatics

- Filter and Separator

- Ceramic filter medium

- atech innovations GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

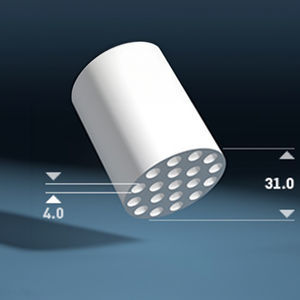

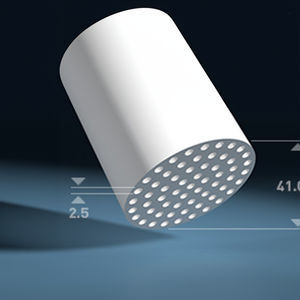

Ceramic filter medium 19/6, 7/6for beerfruit juicefor liquid food products and beverages

Add to favorites

Compare this product

Characteristics

- Material

- ceramic

- Applications

- for beer, for liquid food products and beverages, for viscous liquids, fruit juice

- Other characteristics

- membrane, for high temperatures, for membrane filters, adjustable, integrated

- Pore size

Min.: 6 µm

Max.: 8 µm

Description

Filtration for beer production

High-quality filtration for beer production

Ceramic membranes offer a first-class solution for residual beer filtration and make a significant contribution to the efficiency and sustainability of beer production. They enable waste-free filtration and are ideal for removing yeast cells from the residual beer.

Advantages of ceramic membranes

Faster cleaning and shorter service life: Ceramic membranes can withstand higher temperatures and are chemically resistant, allowing for faster and more effective cleaning.

More efficient beer production: The efficient removal of yeast cells increases yield and improves beer quality.

Long service life: high-quality ceramic ensures a long service life and high sustainability.

In this way, it reduces maintenance and therefore operating costs in the medium and long term.

Membrane filtration is a process in which solids are separated from soluble components in the feed water using pressure. Membranes act as semi-permeable barriers that can trap or allow particles to pass through, depending on the pore size. Suspended solids and dissolved substances with a high molecular weight in the feed water are retained by the membrane, while water and substances with a low molecular weight pass through the membrane as product water.

Microfiltration can increase total beer production by 1 - 1.5 %.

Up to 50 % of the filtered residual beer can be returned to the main beer stream.

. VCF (Volume Concentration Factor) = 2

. Can be regenerated at any time in the filtration system - no replacement necessary

Catalogs

No catalogs are available for this product.

See all of atech innovations GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Liquid separator filter

- Filter for industrial applications

- Pressure separator filter

- Water separator filter

- In-line filter

- Process separator filter

- High-performance pre-filter

- Separator filter for the food industry

- Filter for chemical applications

- Capsule filter

- Membrane filter

- Water treatment filter

- Corrosion-proof separator filter

- High-temperature filter

- Rugged separator filter

- Process water filter

- Ceramic filter

- Sludge treatment filter

- Corrosive liquid filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.