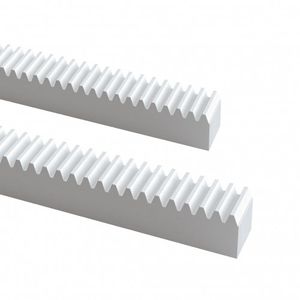

Straight-toothed rack and pinion 50179004precisionlinearhigh-performance

Add to favorites

Compare this product

Characteristics

- Teeth

- straight-toothed

- Other characteristics

- precision, linear, high-performance

- Length

1,000 mm

(39.37 in)

Description

Our new UHPR (Ultra High Precision Rack) racks combine the best of both worlds - the extraordinary quality of the toothing in the overall pitch error and a very low tooth thickness fluctuation. Both ensure high positioning accuracy and the setting of the smallest possible linear play between the pinion and rack. At the same time, subordinate features are generated in a process-optimized manner, so that a rack of extraordinary quality is created at an attractive price.

Developed especially for applications in which precise positioning, high repeatability and thus very high precision are required. Machines such as laser cutting systems or machines for processing aluminium profiles require precise drive systems. The UHPR rack is an essential part of such a price-sensitive drive system and is therefore predestined for such applications. The combination with a high-precision ATLANTA Gear and ATLANTA Servo Angle Gear Unit enables extremely low-backlash and smooth-running rack drives to be implemented. Trust the rack and pinion drive „Made by ATLANTA“

Features of the new UHPR racks

Module 2 and 3

Maximum feed force: 19,5 kN (m=2) or 28,5 kN (m=3)

Total pitch error GTf/1000mm = 0,030mm

Tooth thickness tolerance -15µm

Case hardening steel acc. ATLANTA-Standard for maximum hardness and high resistance against wear.

Teeth hardened with the ATLANTA high-performance hardening process

Rack profile ground on all sides for maximum precisionand minimal lear play

Catalogs

No catalogs are available for this product.

See all of ATLANTA‘s catalogsRelated Searches

- Planetary gearbox

- Right angle gearbox

- Precision gearbox

- Multi-stage gearbox

- Two-stage gearbox

- Bevel gearbox

- High-performance gearbox

- High load capacity gear reducer

- Straight-toothed sprocket wheel

- Servo motor gearbox

- Gear rack

- Ball screw

- Straight-toothed gear

- Straight-toothed gear rack

- Hub sprocket wheel

- Servo-gearbox

- Chain sprocket wheel

- Custom gearbox

- Helical gear

- Spur gear

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.