- Materials - Tools - Components

- Auto body shop equipment

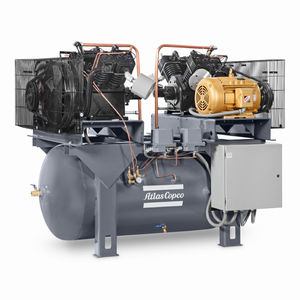

- Scroll compressor

- Atlas Copco Construction Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

Scroll compressor SF series airelectricfixed

Add to favorites

Compare this product

Characteristics

- Technology

- scroll

- Type

- air

- Power source

- electric

- Portability

- fixed

- Lubrication

- oil-free

- Application domain

- for food applications

- Applications

- laboratory, discharge, flexible

- Pressure

Min.: 8 bar

(116.03 psi)Max.: 10 bar

(145.04 psi)- Flow

Min.: 1.9 l/s

(0.5 us gal/s)Max.: 40.8 l/s

(10.78 us gal/s)- Power

Min.: 1.5 kW

(2.04 hp)Max.: 22 kW

(29.91 hp)- Weight

105 kg, 110 kg, 120 kg, 365 kg, 375 kg

(231.5 lb, 242.5 lb, 264.6 lb, 804.7 lb, 826.7 lb)- Noise level

65 dB, 67 dB, 68 dB, 72 dB, 73 dB

Description

Atlas Copco belongs among one of the most expert scroll air compressor manufacturers. The SF and SF+ oil-free scroll compressors deliver absolutely pure oil-free air with supreme energy efficiency.

SF Scroll compressors

The SF and SF+ plus scroll compressors join our lineup of oil-free air technologies such as screw compressors, tooth and centrifugal, giving you, the customer, the perfect option for your needs and operations. This reliable scroll compressor is hosted in a small package, resulting in a small footprint.

Advanced technology

The SF series answers your demands through innovative technologies and supreme energy efficiency without compromising quality. The SF and SF+ series comes fully loaded with the state of the art features such as high-end controller Elektronikon®.

100% oil-free air

As oil-free compressed air is a prerequisite for many manufacturing processes, we ensure consistent oil-free air by preventing oil from entering your compressed air system.

Certified

The SF and SF+ are certified Class 0 (ISO 8573-1). Refers to zero risks of contamination, damages or unsafe products and losses from operational downtime.

Advanced scroll air compressor technology

Air compression is achieved by the interaction of a fixed and orbiting scroll. Air at inlet pressure enters the compression chamber at the exterior side of the scroll element. Once the air is drawn in, the orbiting scroll seals off the inlet port. As the scroll continues its orbit motion, the air is progressively compressed into an increasingly smaller ‘pocket’. A continuous compressed airflow leaves the scroll element through a discharge port in the center of the fixed scroll. This process

Catalogs

No catalogs are available for this product.

See all of Atlas Copco Construction Tools‘s catalogsOther Atlas Copco Construction Tools products

Air compressors

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Reciprocating compressor

- Oil-injected compressor

- Dry compressor

- Compact compressor

- Screw compressor

- Mobile compressor

- Low-noise compressor

- Cooled compressor

- Tank-mounted compressor

- Multi-stage compressor

- Gas compressor

- High-efficiency compressor

- Oil-lubricated compressor

- Air-cooled compressor

- Two-stage compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.