- Materials - Tools - Components

- Auto body shop equipment

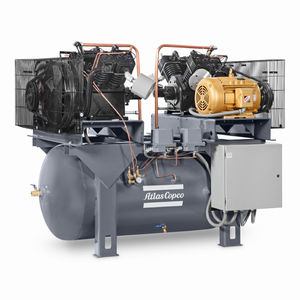

- Rotary compressor

- Atlas Copco Construction Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

Rotary compressor ZEairpneumaticstationary

Add to favorites

Compare this product

Characteristics

- Technology

- rotary

- Type

- air

- Power source

- pneumatic

- Portability

- stationary

- Lubrication

- oil-free

- Application domain

- industrial

- Other characteristics

- low-pressure

- Pressure

Min.: 1 bar

(14.5 psi)Max.: 4 bar

(58.02 psi)- Flow

Min.: 239 m³/h

(8,440.21 ft³/h)Max.: 7,510 m³/h

(265,213.15 ft³/h)- Power

Min.: 30 kW

(40.79 hp)Max.: 522 kW

(709.72 hp)

Description

With a pressure up to 4 bar(g) / 58 psi and a flow up to 9,000 m3/h / 5300 cfm our low pressure rotary screw compressors are unique on the market, suited for a range of industrial applications such as pneumatic conveying applications, truck unloading, and fluidization.

Reducing your operational costs

As energy costs are a compressor’s biggest lifecycle cost, it’s crucial that you consider the energy efficiency aspect of a compressed air installation when searching for your next compressed air investment. We are always looking for new ways to increase the energy savings of your production process, whether that means raising the industry standards for all low pressure screw compressors, optimizing our solutions to fit each process, or offering you additional ways to recover energy.

High uptime - innovative core design

Our ZE/ZA positive displacement screw compressors are designed with the highest reliability in mind, helping you avoid unexpected downtime of your process. Reliability starts at the core of our units: with our components. The cooling jacket cools both bearings and the element housing to keep the element at the lowest possible temperature, which increases the lifetime of your components. Furthermore, the Elektronikon ® Mk 5 precisely controls the oil temperature to ensure optimal oil lubrication of the components for the best performance.

A complete package: avoid unexpected installation costs

The whole is greater than the sum of its parts: by offering you a fully equipped unit that is ready for operation upon arrival, you not only avoid any unexpected installation costs,

Catalogs

No catalogs are available for this product.

See all of Atlas Copco Construction Tools‘s catalogsOther Atlas Copco Construction Tools products

Air compressors

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Reciprocating compressor

- Oil-injected compressor

- Dry compressor

- Compact compressor

- Screw compressor

- Mobile compressor

- Low-noise compressor

- Cooled compressor

- Tank-mounted compressor

- Multi-stage compressor

- Gas compressor

- High-efficiency compressor

- Oil-lubricated compressor

- Air-cooled compressor

- Two-stage compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.