- Materials - Tools - Components

- Auto body shop equipment

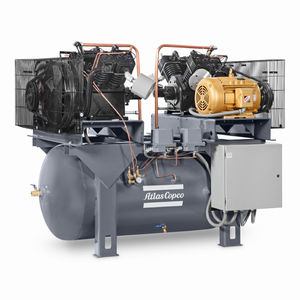

- Piston compressor

- Atlas Copco Construction Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

Reciprocating compressor LE seriesairelectricfixed

Add to favorites

Compare this product

Characteristics

- Technology

- reciprocating

- Type

- air

- Power source

- electric

- Portability

- fixed

- Lubrication

- oil-lubricated

- Application domain

- industrial

- Other characteristics

- tank-mounted, single-stage, high-performance, medium-pressure

- Pressure

10 bar

(145.04 psi)- Flow

Min.: 3.4 l/s

(0.9 us gal/s)Max.: 31.7 l/s

(8.37 us gal/s)- Power

Min.: 1.5 kW

(2.04 hp)Max.: 15 kW

(20.39 hp)- Noise level

Min.: 63 dB

Max.: 78 dB

Description

An Atlas Copco LE compressor is your high-performance industrial air solution. The 10-bar generates quality air at the lowest operating temperatures in the industry and with minimal oil carryover.

LE medium-pressure industrial piston

The single-stage oil-lubricated reciprocating compressor allows filtered air to enter both cylinders through the inlet valve. The piston is driven forward through the connection rod attached to the balanced crankshaft. Maximum operating pressure is 10 bar (145psi) and capacities range from 3.4 up to 31.7 l/s at 50 Hz, 8.3 to 79.8 cfm at 60 Hz. Air compressed in the cylinders leaves through the outlet valve when the pressure reaches 10 bar (145psi).

Total reliability

LE compressors are exceptionally reliable, with the lowest operating temperatures in the industry, and offer quality air with low oil carryover.

Built for industry

Built with durable and high-quality materials, they ensure quality performance and a long product lifetime

Easy installation and service

Thanks to the 'plug and play' design, you can expect easy installation of the compressor. While the accessibility of all components and service points enables easy maintenance.

Reduced energy use

The direct drive arrangement results in no transmission losses. Operational costs are further reduced through the use of highly durable components and a start-stop system instead of load-unload.

Compact design

The LE compressor block is directly coupled to the motor and is built with lightweight materials. This provides excellent cooling and smooth integration in small spaces.

Save floor space

Our LT compressor is ideal for customers who have limited space requirements.

Catalogs

No catalogs are available for this product.

See all of Atlas Copco Construction Tools‘s catalogsOther Atlas Copco Construction Tools products

Air compressors

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Reciprocating compressor

- Oil-injected compressor

- Dry compressor

- Compact compressor

- Screw compressor

- Mobile compressor

- Low-noise compressor

- Cooled compressor

- Tank-mounted compressor

- Multi-stage compressor

- Gas compressor

- High-efficiency compressor

- Oil-lubricated compressor

- Air-cooled compressor

- Two-stage compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.