- Hydraulics - Pneumatics

- Filter and Separator

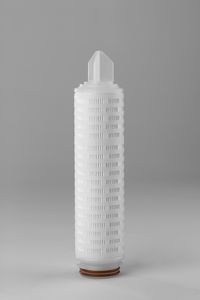

- Beverage filter cartridge

- Atlas Copco Process Filtration

Pleated membrane filter cartridge SMEwaterfor solventsbeverage

Add to favorites

Compare this product

Characteristics

- Media

- water, for solvents, beverage

- Type of filtration

- for micro-filtration

- Material

- PES

- Applications

- for food applications, for chemical applications, for pharmaceutical applications, high-purity

- Domain

- industrial, for the pharmaceutical industry, for the chemical industry, for the cosmetics industry, for the wine industry, for the food and beverage industry

- Other characteristics

- pleated membrane, membrane

- Removal rating

Max.: 1.2 µm

Min.: 0.1 µm

Description

SME filters provide safe, reliable and efficient bioburden control and sterilization of valuable liquids used in Food & Beverage, Pharmaceutical and Chemical industries.

The filters effectively retain particles and micro-organisms through a single layer asymmetric, hydrophilic PES membrane characterized by low extractable and protein binding. The filter media with support layers is integrated into a robust cage or housing making it suitable for nearly all operation, service and cleaning conditions. The product complies with food contact regulation 21 CFR §177 - 182 and (EC) No 1935/2004 and subsequent amendments.

Compatability

SME filter's hardware is completely made from polypropylene utilizing thermal welding techniques to seal all the components thus optimizing device integrity, thus assuring a broad chemical compatibility with a large nμmber of solvents, acids and bases. Polypropylene is a highly chemically resistant material, enabling the filters to be chemically regenerated. The all polypropylene construction guarantees a small extractable footprint.

Key Features

• Wide range of ratings and devices

• Low extractable and protein binding.

• Thermally bonded: no surfactants or binders

• 100% integrity tested

Applications

Thanks to its chemical compatibility SME filters are widely used in Food & Beverage, Pharmaceutical, Cosmetics and Chemical Industries.

• Retention of particles and micro-organisms in liquids

• Bioburden control and sterilization

• Edible liquids: bottled water, beer, wine, spirits, juices, softdrinks, non-carbonated drinks, etc.

• Non-edible liquids: water, serμms, formulations, WFI,aggressive solvents, chemicals, etc.

Catalogs

SME

3 Pages

Other Atlas Copco Process Filtration products

Pleated membrane filter cartridges

Related Searches

- Atlas Copco filter cartridge

- Atlas Copco industrial filter cartridge

- Atlas Copco fine filter cartridge

- Atlas Copco general purpose filter cartridge

- Atlas Copco water filter cartridge

- Atlas Copco plastic filter cartridge

- Atlas Copco pleated filter cartridge

- Atlas Copco chemical product filter cartridge

- Air filter cartridge

- Atlas Copco membrane filter cartridge

- PP filter cartridge

- Atlas Copco filter cartridge for the chemical industry

- Metal filter cartridge

- Oil filter cartridge

- Atlas Copco solvent filter cartridge

- Atlas Copco process filter cartridge

- Atlas Copco foodstuff filter cartridge

- Atlas Copco gas filter cartridge

- Atlas Copco filter cartridge for the pharmaceutical industry

- Atlas Copco beverage filter cartridge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.