- Metrology - Laboratory

- Metrology and Test Equipment

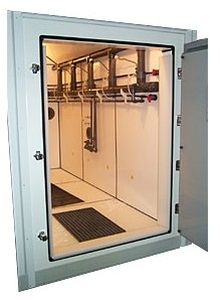

- Cyclic corrosion test chamber

- Atlas Material Testing Technology

Cyclic corrosion test chamber BCX series for automobilesfor the aeronautical industry

Add to favorites

Compare this product

Characteristics

- Test type

- cyclic corrosion

- Product applications

- for automobiles

- Application domain

- for the aeronautical industry

- Capacity

565 l, 850 l, 1,130 l, 2,550 l, 3,115 l

(149 gal, 225 gal, 299 gal, 674 gal, 823 gal)- Temperature

55 °C, 71 °C

(131 °F, 160 °F)- Interior length

50 in, 75 in, 76 in, 89.25 in

- Interior height

25 in, 30 in, 45.5 in

- Interior depth

29 in, 37 in, 45 in, 73.25 in

- External length

76 in, 97 in, 106 in, 111 in

- External height

56 in, 72 in, 85 in

- External depth

35 in, 43 in, 52 in, 90 in

Description

Basic cyclic tests are used to qualify a coating or material for a specific end use on a pass-fail basis, or determine the probability of corrosion of a specific material.

Applications include: Aerospace, Appliances, Automotive, Government, Marine Craft, Paints/Coatings, Research, and Telecommunications.

Features

◦ Reinforced fiberglass cabinet, exposure lined with gel coat

◦ Solution reservoir - 35 gal (132 L)

◦ Clear cover with dual magnetic Santoprene gasket (BCX9000 comes with opaque Polypropylene cover)

◦ Peaked cover prevents dripping of condensate onto samples

◦ Exposure zone heated by titanium rod heater

◦ Heated humidifying (bubble) tower with air relief valve

◦ Exposure zone temperature up to 131 °F (55 °C) - Hight temperature option up to 160 °F (71 °C)

◦ Omni-Fog Dispersion Tower or Omni-Fog II Dispersion System, fully adjustable. Built-in support ledges, front and back

◦ Wet Bottom Drain Assembly; heated, with auto fill for higher and more uniform humidity (n/a BCX11000)

◦ Air-assisted Cover Lifters on BCX9000 and BCX11000

◦ Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions)

◦ BCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 1.93 x 0.9 x 1.4 m

◦ BCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 2.46 x 0.9 x 1.4 m

◦ BCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 2.46 x 1.1 x 1.4 m

◦ BCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 2.69 x 1.32 x 2.16 m

◦ BCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 2.82 x 2.29 x 1.83 m

Catalogs

Network of Weathing Catalog

68 Pages

Other Atlas Material Testing Technology products

Corrosion Cabinets

Related Searches

- Test cabinet

- Temperature test cabinet

- Climatic test chamber

- Humidity test cabinet

- Quality control test cabinet

- Stainless steel test cabinet

- Automobile test cabinet

- Vehicle test chamber

- Test chamber with window

- Test chamber on casters

- Durability test chamber

- Test chamber for the aeronautical industry

- Floor-standing test cabinet

- Thermostatic test chamber

- Stability test chamber

- Test chamber for the pharmaceutical industry

- Accelerated test chamber

- Walk-in test chamber

- High-capacity test chamber

- Solar panel test chamber

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.