- Products

- Catalogs

- News & Trends

- Exhibitions

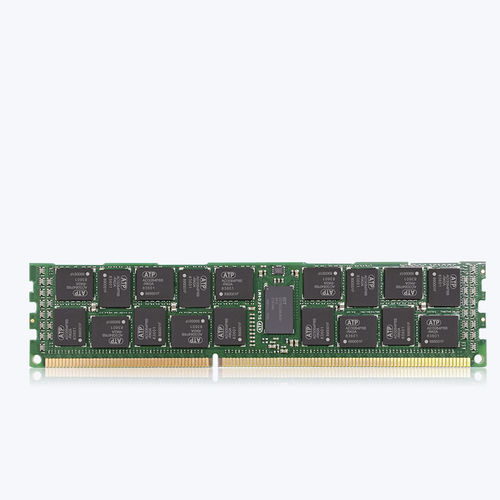

DDR3 SDRAM memory module DDR3 8Gbit

Add to favorites

Compare this product

Characteristics

- Type

- DDR3 SDRAM

- Memory capacity

8 GB, 16 GB, 32 GB

Description

As the DRAM market makes a steady migration to DDR4 memory, several key manufacturers have already announced end-of-life (EOL) production of DDR3 modules based on high density DDR3 8 Gbit components including EOL notice of the components. However, a sizable number of customers in the networking and embedded industries are still unable to shift to the latest generation and continue to use legacy systems requiring specific DDR3 memory such as VLP RDIMMs or high-density SO-DIMMs. To avert a supply shortage that could adversely affect these customers’ business operations, ATP has decided to provide its own DDR3 8 Gbit components for these modules.

ATP-Built, Characterized and Tested from IC to Module

ATP’s own-built DDR3 modules consist of meticulously characterized and tested high-quality integrated circuits (ICs). The components are manufactured according to ATP’s exacting standards using 2x nm manufacturing process technology and are tested via an extensive component test program to improve the overall memory module performance. ATP DDR3 8 Gbit components are free from row hammer effects, thus preventing any disastrous random bit flips caused by the electrical charge of cells leaking to adjacent cells and successively writing data to them. At module level, ATP implements 100% test during burn-in (TDBI) into the production flow to guarantee the high-quality module.

Key Features

ATP-Built, Characterized and Tested from IC to Module

100% test during burn-in (TDBI)

Available in monolithic 8 Gb one-chip select (1CS)

Available in 8 Gb DDP two-chip select (2CS)

Longevity Support

Catalogs

Memory & Storage Solutions

48 Pages

Related Searches

- SSD

- Internal SSD

- SATA SSD

- Memory card

- Flash memory card

- DRAM memory module

- 2.5" SSD

- Industrial memory card

- 16 GB memory card

- 32 GB memory card

- 8 GB memory card

- 64 GB memory card

- USB Flash drive

- 128 GB memory card

- 4 GB memory card

- SD memory card

- NAND memory card

- SO-DIMM memory module

- CompactFlash memory card

- MicroSD memory card

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.