- Packing - Handling - Logistics

- Packing and Packaging

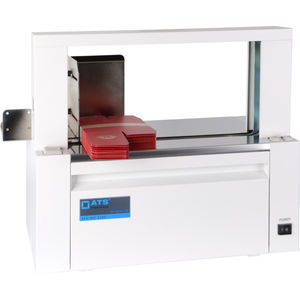

- Table-top banding machine

- ATS-Tanner GmbH Banderoliersysteme

Automatic banding machine US-2000 CL-TS-Lwith touch screentable-topmobile

Add to favorites

Compare this product

Characteristics

- Specification

- automatic, with touch screen, table-top, mobile, with printer, horizontal

- Application

- for small boxes, for the food industry

Description

Flexible high-performance banding system for stacking and bundling up to 150 carton boxes per minute

- Shelf-ready Packaging (SRP) / Retail-ready packaging (RRP)

- Erecting the folding boxes to form rows

- Processing of products of different sizes

- Stacking products

- Bundle products

- Integrated product feeding

- Convertible from left to right

The high-performance banding system takes over pharmaceutical and cosmetic boxes from the cartoning machine. In the turning station, the flat-lying cartons are erected and the desired stack row is formed. The stacks are then banded in the US-2000. Combined with a thermal transfer printer, dynamic and individual product information such as date, time, QR or EAN codes can be printed directly on the bands. Depending on the stack size and infeed speed, up to 30 bandings per minute are possible. Format changeovers are quick and easy.

For format changes, the product guides are adapted by quick adjustments. Thanks to the encoder control in the US-2000 and the brushless AST motor, the system operates extremely reliably even in 24/7 operation. The number of cartons per stack are configured via quick adjustment. The system is operated with a programmable logic controller (PLC) and a touch-screen HMI. The PLC allows high flexibility for customized interfaces or options such as OEE and remote access. The corner-line system is left and right configurable. This means that products can exit the machine to the left or right as desired.

Options

- AST-Motor (Arch Strong Tension)

- Band width 50 mm

- Left or right version

- Thermal transfer printer for product labeling

Catalogs

No catalogs are available for this product.

See all of ATS-Tanner GmbH Banderoliersysteme‘s catalogsOther ATS-Tanner GmbH Banderoliersysteme products

Banding machines

Related Searches

- Roll foil

- Transparent sheet

- Banding machine

- Automatic banding machine

- Packaging foil

- Adhesive sheet

- Banding machine for the printing industry

- Stretch film

- Table-top banding machine

- Banding machine with touch screen

- Mobile banding machine

- Paper belt banding machine

- Banding machine for the pharmaceutical industry

- Horizontal banding machine

- Vegetable banding machine

- Banding machine for the food industry

- Fruit banding machine

- Paper banding machine

- Banding machine with belt conveyor

- Small box banding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.