- Packing - Handling - Logistics

- Packing and Packaging

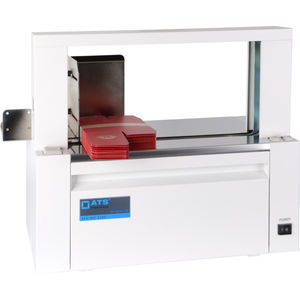

- Mobile banding machine

- ATS-Tanner GmbH Banderoliersysteme

Automatic banding machine US-2000 SIB-TTP-Rwith touch screenmobilewith belt conveyor

Add to favorites

Compare this product

Characteristics

- Specification

- automatic, with touch screen, mobile, with belt conveyor, with printer, horizontal

- Application

- for vegetables, for the food industry

Description

Stainless banding system with integrated thermal transfer printer and optional hot melt glue dispenser for stacking products

- Stacking products

- Printing of variable information

- Stainless steel

- High cycle performance

- Automation of production and packaging lines

- Integration in production line

The US-2000 SIB-TTP-R automatic banding system takes the products directly from the production line by means of an infeed conveyor belt and optionally places a glue strip at the end of the rising belt. The intermediate stacker enables a flowing, uninterrupted production. After stacking, the products are fed to the banding machine by means of a servo axis. Afterwards, the products are banded and ejected by the following stack. At the same time, the next stacks are formed. Depending on the product and the infeed, up to 96 products per minute can be processed and up to 32 stacks can be banded. The integrated thermal transfer printer marks the stacks with variable information such as 1D and 2D codes or price information. The brushless AST unit ensures high performance and availability.

The optional hot-melt glue dispenser enables perfect grip between products with slippery surfaces, even without strong belt tension. In the case of stacks consisting of three products, the middle and the bottom product are each provided with a glue strip.

Options

- AST-Motor (Arch Strong Tension)

- Hot-melt glue dispenser

Catalogs

No catalogs are available for this product.

See all of ATS-Tanner GmbH Banderoliersysteme‘s catalogsOther ATS-Tanner GmbH Banderoliersysteme products

Banding machines

Related Searches

- Roll foil

- Transparent sheet

- Banding machine

- Automatic banding machine

- Packaging foil

- Adhesive sheet

- Banding machine for the printing industry

- Stretch film

- Table-top banding machine

- Banding machine with touch screen

- Mobile banding machine

- Paper belt banding machine

- Banding machine for the pharmaceutical industry

- Horizontal banding machine

- Vegetable banding machine

- Banding machine for the food industry

- Fruit banding machine

- Paper banding machine

- Banding machine with belt conveyor

- Small box banding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.