- Packing - Handling - Logistics

- Packing and Packaging

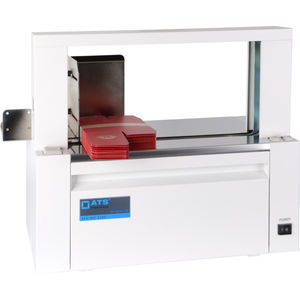

- Table-top banding machine

- ATS-Tanner GmbH Banderoliersysteme

Automatic banding machine US-2100 IBL-CB-P-Rwith touch screenwith belt conveyortable-top

Add to favorites

Compare this product

Characteristics

- Specification

- automatic, with touch screen, with belt conveyor, table-top, with printer

- Application

- for the food industry

Description

Automatic, stainless banding system with just-in-time printer for banding with wide bands in the food industry

- Branding with Banding / Premium Labeling

- Food labeling

- Printing of variable information

- Stainless steel

- Automation of production and packaging lines

The US-2100 IBL-CB-P-R automatic banding system seals and labels e.g. food trays in one step. The system takes the products from a conveyor belt where they are placed either automatically or manually. A second conveyor downstream of the first conveyor separates even closely packed products so that the infeed pusher can move down behind the individual product and transfer it to the US-2100. The side centering system holds the products exactly in position before banding. The sophisticated discharge handling system can be used as a stop to accurately position the bands and convey the last product out of the machine.

The integrated Novexx thermal transfer printer with continuous feed precisely prints variable information such as ingredient lists, best-before dates, or 1D and 2D codes in the space provided on the optional pre-printed band.

The US-2100 banding machine is integrated into the system in such a way that it does not stand on the floor itself. The advantage of this is that no adjustment is required when moving the entire system, even on uneven surfaces. The integrated banding machine can nevertheless be easily removed and used as a stand-alone machine.

The banding system has an output of up to 26 cycles per minute and can be easily and quickly changed over to other products. The US-2100 IBL-CB-P-R is made of stainless steel and is suitable for use in humid environments.

Catalogs

No catalogs are available for this product.

See all of ATS-Tanner GmbH Banderoliersysteme‘s catalogsOther ATS-Tanner GmbH Banderoliersysteme products

Banding machines

Related Searches

- Roll foil

- Transparent sheet

- Banding machine

- Automatic banding machine

- Packaging foil

- Adhesive sheet

- Banding machine for the printing industry

- Stretch film

- Table-top banding machine

- Banding machine with touch screen

- Mobile banding machine

- Paper belt banding machine

- Banding machine for the pharmaceutical industry

- Horizontal banding machine

- Vegetable banding machine

- Banding machine for the food industry

- Fruit banding machine

- Paper banding machine

- Banding machine with belt conveyor

- Small box banding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.