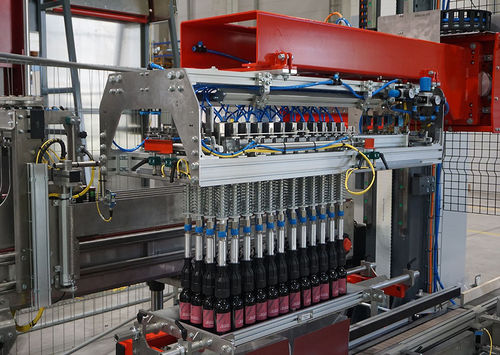

The Pick & Place robot CERTANT PPK packer is used for packing or unpacking cans, round, oval or rectangular glass and plastic bottles into or from plastic boxes, cartons with and without trays. The CERTANT PPK packer is an economical solution for companies with a small to medium production capacity. Different bottle diameters can be processed without changing the gripper head. Formats can be changed rapidly by using format sets.

Thanks to its compact design, the Pick & Place robot CERTANT PPK packer can be integrated into existing filling lines in breweries, wine- or water-filling plants. The innovative gripper changing system facilitates rapid changeover from bottle production to can production. The CERTANT PPK packer can be operated with both a linear and a vibration-driven lane distribution system. The lane rails are fitted with a label protector as standard, thereby ensuring that our customers can present high-quality products to the end consumer.

Highlights:

■ Smooth handling for sensitive products and labels

■ Packing/unpacking of round, oval or rectangular bottles or cans

■ Glass bottles and cans can be processed on the same machine

■ Universal gripper with quick-change coupling

■ Short and economical set-up times

■ Available with automatic or semi-automatic lane distribution system

■ Packing/unpacking into plastic crates, boxes or trays

■ Equipped with the latest efficiency class drives