Fusion® Operations is a manufacturing execution system (MES), providing real-time data for production management.

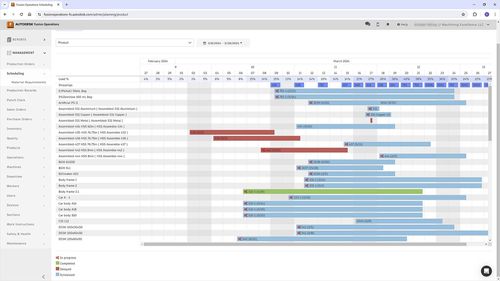

Plan production schedules to enhance the flexibility of job scheduling

Track inventory, monitor workers, and oversee machines to help optimize overall production efficiency

Manage product quality through production traceability to align with industry standards and regulations

Why use Fusion Operations?

Reduce waste and costs

Gain insight into production and identify previously unseen costs

Shorten lead times

Adjust schedules on the fly to quickly adapt to production changes

Minimize shop maintenance

Powerful insights help you anticipate maintenance and minimize production downtime

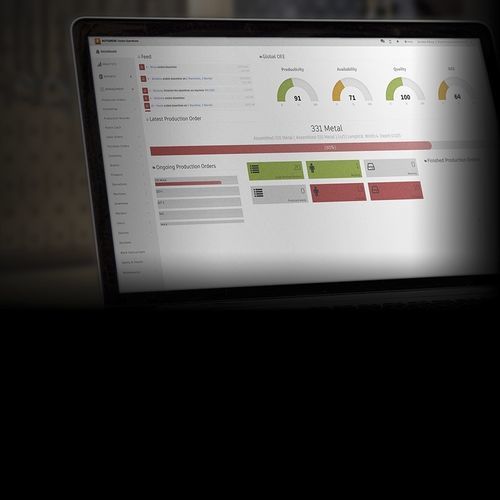

Real-time dashboard and connected manufacturing

Access your data from any device.

Stay connected to workers and colleagues in real-time.

Customize alerts for real-time responses.

Immediate alerts when machines are down or require maintenance.

Visualize workflows

Identify bottlenecks.

Set priorities and avoid overload.

Increase productivity and seamless workflow.

Continuously improve the production system.

Maximize productivity and performance

Track each worker’s performance, in real-time.

Monitor productivity and tasks of team members.

Specify team resourcing: who does what, where, when, and how.

Align shift management with shop floor activity.