Design 3D printing software modelingsimulationslicing

Add to favorites

Compare this product

Characteristics

- Function

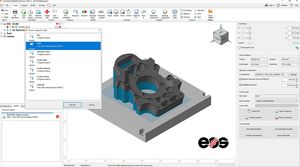

- modeling, slicing, design, simulation

Description

Additive manufacturing, such as 3D printing, is changing the way products are designed and created. Learn more about additive manufacturing software from Autodesk.

What is additive manufacturing?

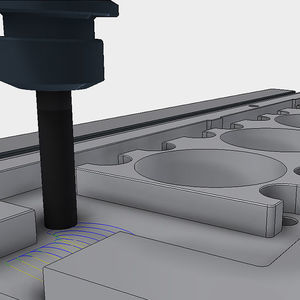

Additive manufacturing, also known as 3D printing, is a process used to create a physical (or 3D) object by layering materials based on a digital model. Unlike subtractive manufacturing, which creates its final product by cutting away from a block of material, additive manufacturing adds material to form its final product.

Additive manufacturing expedites prototyping, allowing designers, engineers, and manufacturers to quickly refine designs, saving time and reducing costs. Additive manufacturing also enables customized manufacturing and promotes sustainability through the reduction of waste and energy consumption.

What is additive manufacturing software?

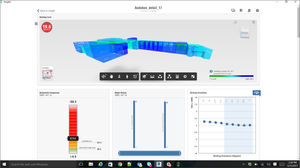

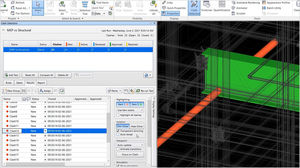

Additive manufacturing software supports and optimizes the entire process of additive manufacturing. It plays a critical role in 3D printing workflows, from design and modeling to planning, slicing, and machine control. The software enables creators to produce fully prepped design files and connect directly to 3D printing machines.

How is additive manufacturing used?

Additive manufacturing is primarily used by engineers, architects, and construction managers, and has replaced manual drafting. Manufacturing software helps users create designs in three dimensions to visualize construction and enables the development, modification, and optimization of the design process. This process helps engineers make more accurate representations and modify them more easily to improve design quality.

Catalogs

No catalogs are available for this product.

See all of AUTODESK‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.