- Industrial machines and equipment

- Furnace and Heat Treatments

- Pasteurizer for the food industry

- AS AUTOMATION SYSTEM HELLAS

- Products

- Catalogs

- News & Trends

- Exhibitions

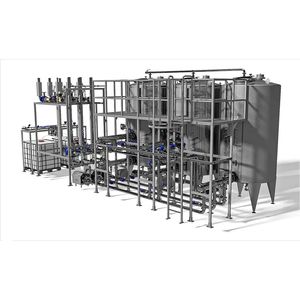

Pasteurizer for the food industry GALAXIASautomaticsteamelectric

Add to favorites

Compare this product

Characteristics

- Applications

- for the food industry

- Operating mode

- automatic

- Other characteristics

- steam, electric, homogenizer

Description

The automatic milk pasteurization solution for all size plants. It has integrated all the equipment and connections for external equipment (separator, homogenizer, deodorizer, standardization unit for fat content, large holder etc.) and it is ready for operation. All the functional parameters can be adjusted by the operator. It is supplied with different automation levels while it can easily be integrated in any plant.

SMART ENGINEERING

Pasteurization is one of the most important processes in the treatment of milk. The GALAXIAS unit is designed and engineered to meet strict hygiene, safety and quality standards. It has integrated all the equipment and connections (separator, homogenizer, deodorizer, large holder etc.) and it is ready for operation. All of the operational parameters are available for adjustment by the operator. It is supplied with different automation levels while it can easily

be integrated in any plant.

AUTOMATED AND OPTIMIZED

The automation routines allow for easy preparation of the pasteurizer circuit following all the necessary pasteurization preparation steps automatically. During production, all the safety measures are followed and actions are taken automatically to safeguard the product. All data are recorded to ensure a safe product and to allow the operator to trace back in time and check them.

Initial filling and final emptying of the milk are done automatically with high accuracy, reducing the milk-water dilution and milk losses to an absolute minimum. CIP procedure at the end of the production is more than easy, since everything works automatically and operator and product safety are both guaranteed.

Other AS AUTOMATION SYSTEM HELLAS products

Prefabricated units

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.