- Industrial machines and equipment

- Printing, Marking and Engraving

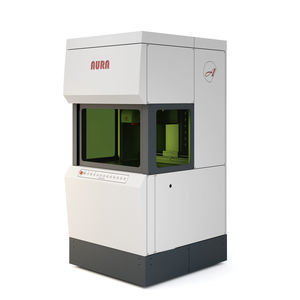

- Fiber laser marking system

- Automator International

Fiber laser marking system UBIfor siliconplasticmetal

Add to favorites

Compare this product

Characteristics

- Technique

- fiber laser

- Applications

- for silicon

- Material

- metal, plastic, ceramic, paper

- Other characteristics

- compact, vertical

Description

Laser system for small and medium-sized productions equipped with a Micro aWave source that allows to create markings comparable to a 20W fiber laser on many materials. The external protective structure is extremely compact, ideal for being used on a work bench. The door opening and closing system is manual with a security locking system and the internal Z axis is electric. Large CE certified inspection windows on three sides offer a complete view of the internal marking area. It is a Class 1 security device.

Ubi Basic sets a laser source with self-adjusting frequency. Belonging to the new a-WaveTM products family, exclusive Automator technology, the UBI Basic source was built by-passing the concept of “power”, being able to mark, depending on the materials and applications, with performance comparable to that of a 20W fiber. And this guarantees excellent results on plastics, metals, anodized, ceramic, polycarbonate, painted and much more

Laser Source Shutter

UBI Basic integrates a shutter housing: this electro-mechanical actuator provides a millisecond shutter operation. During marking, the shutter stays in an open position and then closes when the operation is completed providing a safe condition of lockout. The shutter movement can be controlled by the laser hardware/software or by the I/O signals. An integrated certified safety sensor detects the shutter blade position in the housing, providing a critical information that confirms the state of the shutter position.

Vertical axis

UBI Basic sets an electric Z axis with a large base (200×200 mm 7,9×7,9 inches) for an easy setting of the piece to be marked, for a maximum weight of 5 Kg or 11 lbs.

VIDEO

Catalogs

Laser

23 Pages

Related Searches

- Marking machine

- Laser marking workstation

- Metal marking workstation

- Benchtop marking workstation

- Plastic marking workstation

- Industrial marking workstation

- Automated marking machine

- Compact marking workstation

- High-speed marking machine

- Fiber laser marking machine

- Aluminum marking workstation

- Dot peen marking machine

- Integration marking machine

- Air-cooled marking machine

- Hand-held marking machine

- Electronic component marking machine

- CO2 laser marking machine

- Pneumatic marking machine

- Paper marking machine

- Wood marking machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.