- Metrology - Laboratory

- Inspection and Monitoring

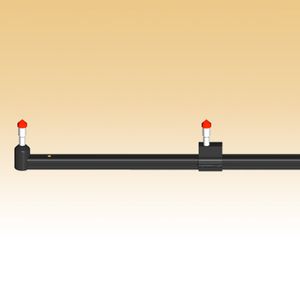

- Mechanical inspection system

- Autorobot Finland OY

Mechanical inspection system for the automotive industry

Add to favorites

Compare this product

Characteristics

- Technology

- mechanical

- Applications

- for the automotive industry

Description

Autorobot's measuring systems are unique in the industry. Total-vehicle accessibility makes measuring of all structures – chassis, frame, suspension, under the hood, fenders, even the roof – easy and accurate. Modular components keep the system from being cumbersome and bulky, making it a snap to set up and store away. Lightweight aluminum beams clamped to the straightening bench on either side of the vehicle are the support for both the chassis measuring bridges and our unique upper body measuring arch. The easily maneuverable bridges and arch glide smoothly on roller bearings, making effortless work of setting the measuring rods. It is the overhead measuring arch, moving freely over the entire length of the vehicle, that makes the Autorobot system a standout in the industry. Accurate upper body measurements have the greatest effect on top-quality auto body repair. The measuring system can also be used during repair work. Kept in place while straightening, it can show the direction and extent of the straightening. Ongoing since 1980, Autorobot's collection of 3D measuring data provides the specs for accurate straightening work and provable results. These data files, available on disk and/or the Internet, contain information such as: McPherson upper end mounting points, front and rear fender angles, vehicle A, B and C pillars, sill box sections and roof angles in addition to the chassis references, much of which is offered by Autorobot only.

Catalogs

No catalogs are available for this product.

See all of Autorobot Finland OY‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.